Pumps are required at all stages within the pharmaceutical industry, whether this be processing, unloading, dosing, mixing or transferring individual ingredients or the final product. The pharmaceutical industry is one that has very specific requirements with regards to the equipment used, and Castle Pumps understand that the pumps supplied to this industry need to meet very strict sanitary standards.

Pharmaceutical pumps need to be constructed in a way that eliminates any risk of impairment or contamination of the pumped medium. P3-A sanitary standards were introduced to ensure that no equipment used in the production of pharmaceutical ingredients would impact upon its strength, safety, purity or quality. Therefore, pumps used must be made of approved materials such as polished stainless steel, all internal surfaces need to be smooth to prevent bacteria from gathering and shear sensitive pumps should be used to avoid product alteration.

Having dealt with the pharmaceutical industry for many years, Castle Pumps have built up the expertise to ensure that where required, all pumping solutions specified are compliant with the 3-A regulations and are perfectly matched to the application in question.

Whether the pump is for metering a precise batch of active ingredient into a solution, mixing all ingredients of a lotion together, powder coating tablets or transferring medicines to the machine that fills the bottles, Castle Pumps have the solution. Some of the specific types of pumps that we supply to the pharmaceutical market include:

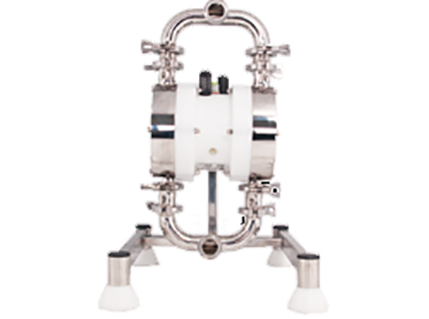

Sanitary / hygienic pumps – With pharmaceutical items it is vital that their sanitary conditions are maintained and therefore the pump must be constructed of non-contaminating materials and with no crevices where bacteria could harbour. It is also important that they are constructed in a way that allows them to be easily taken apart and cleaned, or so they can be Cleaned in Place (CIP).

Shear sensitive pumps – There are many pharmaceutical products that can be altered or damaged by the shearing motion of some pumps. Therefore, products such as tablets that may get crushed or creams that may become more liquidised often require a low shear pump.

Dosing pumps – It is important within pharmaceutical production that very precise quantities of active ingredients or chemicals are added to a mixture. This highly accurate batching requires a dosing pump.

Aggressive fluid pumps – The production of pharmaceutical items often involves the handling of aggressive or abrasive liquids such as acids. Therefore certain pumps such as magnetic drive pumps are popular, as there are no mechanical seals that are susceptible to wearing and causing leaks.

Castle Pumps are fully accredited to enable you to buy with confidence. Our accreditation includes:

![]() A division of the CTS Group, Part of Flow Max Ltd.

A division of the CTS Group, Part of Flow Max Ltd.