Customer: Power Station

Location: South America

Equipment supplied

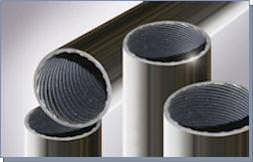

1.8KM of Rifled Boiler Tubes in various sizes and specifications

Enquiry

A power plant company had a boiler tube bank built by Babcock and Wilcox with rifled boiler tubes which required replacing. The lead time seemed long from the manufacturer and the prices seemed high so Castle Pumps were asked to quote. Only part of the boiler tube specification was known and we were contacted to see if we could help specify a solution.

Solution

Castle Pumps have a strong relationship with a boiler tube manufacturer and supply all types of boiler tubes including straight, finned and rifled. As only part of the specification was known, further information was required in order to quote. We asked for measurements to be made of the boiler tubes in order for the tube to be specified correctly; however the client preferred if we could measure the tubes to ensure exact replacements were supplied.

Although the client was located overseas this was not an issue. A sample was requested which was then measured by our in house technical team, the thickness was checked, the angle of rifle checked and then this was verified by the factory. The original boiler tubes had a length of 12m which had been welded. As welds are a common reason for boiler tube failure, we proposed that the client utilises longer, 20m tubes to reduce the number of welds to be performed on site and consequently lowers the risk of premature failure. The specification was then issued for the client to check which was duly signed off allowing the tubes to enter production to their required specification.

Our customer also wanted independent verification of the boiler tubes and that they had been made according to specification as they had had issues in the past from other low quality suppliers were tubes had been out of specification. This was not a problem as Castle are happy to not only have boiler tubes independently verified by Lloyds, DNV, Bureau Veritas or SGS but also pumps, valves, flow meters, expansion joints and other ancillary items. The tube specification matched and a report was produced for our customer prior to shipping.

Castle Pumps have so far supplied over 10KM of boiler tubes to power plants worldwide in varying grades from API5L, to ASTM and T grades. Our boiler tubes comply with various Global specifications including DIN17175, DIN2391, DIN1629, EN10216-1/2, EN10305, EN10208, EN10297 and ASME grades.