Customer: Wood & Laminate Flooring Company

Application: Viscous adhesive pump

Location: UK

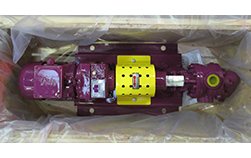

Equipment supplied

1 x 0.37 Kw internal eccentric gear pump with pressure relief valve

- Application: Gravity fed adhesive transfer from an IBC to an adhesive bead applicator.

- Installation: Horizontal with Inlet / Outlet: 1" (Threaded) at 90 deg.

- Fluid: Adhesive

- Viscosity: 4000 - 5000cP

- Flow: 2 - 3l/min

- Discharge pressure: 0.3 Bar

- Pump body: GG 25 Cast iron

- Rotors: 1050 Steel, Heat treated

- Shafts: 1050 Steel, Heat treated

- Bearings: Bronze

- Sealing: Soft seal / Packing gland

- Voltage: 400V

- RPM: 85

Enquiry

Castle Pumps received an enquiry from a new customer in the UK that was looking to feed an adhesive fluid to a bead applicator for use in timber construction. The customer wanted to gravity feed the fluid from the bottom of an IBC to a piece of machinery that applies the highly viscous fluid in a specific way to products in their production line.

Solution

Our first consideration was the high viscosity of the fluid, which was 4000 - 5000cP, so immediately we selected a gear pump for the application knowing it would be more than capable of handling the thickness of the fluid. After consulting with the customer we settled on a 90deg configuration as we are always cautious of the space available and pride ourselves on our ability to cater for any special requests. Using a gear pump running at such a low speed we were able to achieve the low flow rate required by the customer to feed into his production line.