Centrifugal pumps are one of the most popular pumping solutions in the world due to their highly efficient and simple design. However, just like any other pump, they can also suffer from pump failure and damage if preventive maintenance is neglected. So if you have invested in a centrifugal pump for your site, you need to ensure that you have a maintenance schedule in place, that will not only extend your system's life but also reduce operating costs.

Even if you have invested in a high-quality centrifugal pump like Azcue, which means that you have a great pump solution in place, preventive maintenance is essential to keep your process running smoothly and prevent any unexpected downtime and costs. Centrifugal water pumps have hundreds of components that keep them running smoothly and are integral to providing effective pump operation. Therefore, consistent maintenance can not only prevent pump failures but also help your engineers to identify the source of the problem faster, as they will have enough maintenance history recorded to refer back to. To help you put together your centrifugal pump maintenance schedule, we asked our technical sales engineer for a good preventive maintenance strategy…

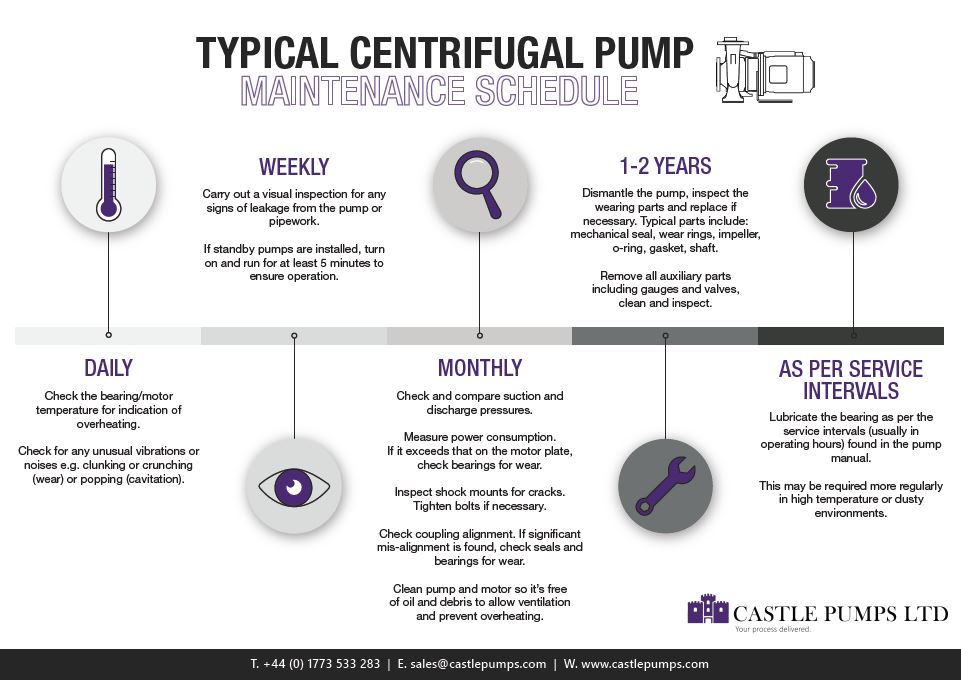

Don't have time to read the whole article. Download our helpful infographic that you can use to implement a centrifugal pump maintenance schedule. Click here

Centrifugal pump maintenance schedule

If you have a centrifugal pump on-site and don't already have a maintenance programme in place, then you are probably asking yourself all of these questions: How often do you need to perform routine maintenance or replace parts? Which pump components must be checked more often, and when should you schedule the pump maintenance? What spare parts do you need to stock to prevent any pump downtime?

Planning preventive maintenance of centrifugal pumps can be confusing, especially if you don't know where to start. So we asked our technical sales engineers to give us their recommendations for a centrifugal pump maintenance schedule. Here is their advice and an example of a maintenance plan…

Daily

Best practice is to carry out a visual inspection of the pump installation on a daily basis. Spotting an issue early is one of the best troubleshooting methods and can preventing pump breakdowns. Here are some of the things to look out for:

- Check the bearing/motor temperature for indication of overheating.

- Check for any unusual noises as these are the first signs of a problem e.g. clunking or crunching (wear) or popping (cavitation).

- Check for any excessive vibration as this can indicate an impending breakdown, and it can result in misalignment, cavitation, or wear.

- Record any irregularities in the operation of a pump. This will help you to keep track of the pump operation.

2.png)

Weekly

Just like the daily inspection, you should look for any abnormalities but this time, pay close attention to the following centrifugal water pump components:

- Carry out a visual inspection for any signs of leakage from the pump or pipework. If standby pumps are installed, turn on and run for at least 5 minutes to ensure operation.

- Check for a sudden decrease in the efficiency of your centrifugal pump. This may be due to a broken shaft seal. Inspect the shaft seals for any physical signs of damage/leakage and replace the seal where necessary.

Monthly

Following our centrifugal pump maintenance schedule, you will need to check the following pump components once a month to ensure that your pump is running efficiently and prevent any potential failure or damage:

- Check and compare suction and discharge pressures.

- Inspect shock mounts for cracks.

- Tighten bolts if necessary to make sure the pump is securely installed.

- Determine if the mechanical seals are in good condition.

- Change the oil every three months (2000 operating hours) at a minimum.

- Measure power consumption and if it is exceeding that on the motor plate, check bearings for wear.

- Check coupling alignment. If significant misalignment is found, check seals and bearings for wear. Clean the pump and motor, so it's free of oil and debris to allow ventilation and prevent overheating.

1-2 years

Less often but very important is to thoroughly inspect the whole centrifugal pump and consider changing some of the spare parts to ensure that the pump operates in optimal conditions. Here are our recommendations:

- Dismantle the pump, inspect the wearing parts and replace them if necessary. Typical parts include: mechanical seal, wear rings, impeller, o-ring, gasket, shaft. Remove all auxiliary parts, including gauges and valves, clean and inspect.

- Replace certain components such as the mechanical seals and impellers to prevent leaking and other issues. The best practice is to hold stock of typical wearing parts on-site to prevent any delay in maintaining your pump if any components fail.

As per service intervals

Always make sure to create a maintenance schedule that is consistent with the manufacturer's guidelines and keep in mind that certain components need to be maintained based on their service intervals:

- Lubricate the bearing as per the service intervals (usually in operating hours) found in the pump manual. This may be required more regularly in high-temperature or dusty environments.