24th March 2015

Anaerobic Digestion (AD) is an increasingly prevalent topic within waste reduction, environment and energy related discussions and activity. It refers to the process of biomass, such as slurry and manure, food waste and crops and residues, being broken down by micro-organisms in the absence of air. Once added to a sealed tank or digester micro-organisms begin digesting the biomass, which in turn releases a biogas that can be used to generate renewable energy.

In their Anaerobic Digestion Strategy and Action Plan Annual Report update last month, DEFRA announced the AD highlights of the last year. By September 2014, the number of AD plants in the UK had grown to 140, with more than 200 further sites having received planning permission for future construction. In addition to this, installed capacity of power generated by AD was almost quadruple by the end of 2014 in comparison to when the strategy was first released in 2011. In 2013 for example, nearly 1.5TWh of electricity was generated, which gives great confidence that the aim outlined by the strategy to achieve between 3 and 5TWh by 2010 is obtainable.

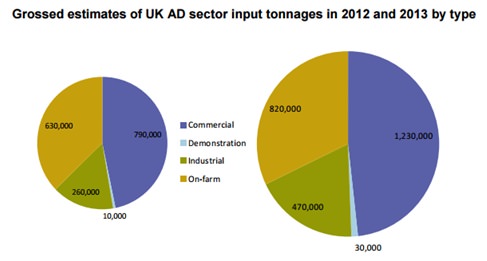

As detailed in the graphs below (data taken from the 2013 UK Anaerobic Digestion Industry Report) there has also been a clear increase in the quantity of biomass input in AD systems.

Growth in the Anaerobic Digestion market is set to continue according to the report, which poses a great opportunity for all industries that supply the sector. Castle Pumps supply a range of pumping solutions to AD plants, namely peristaltic pumps and progressive cavity pumps for transferring the high-solid biomass slurries into the digester, as well as the remaining digestate left over that needs to be transferred for storage before being used as fertiliser. An example project we have worked on can be viewed here.

Castle Pumps are fully accredited to enable you to buy with confidence. Our accreditation includes:

![]() A division of the CTS Group, Part of Flow Max Ltd.

A division of the CTS Group, Part of Flow Max Ltd.