The Importance of Chemical Compatibility

When you are trying to source a pump, a fitting or some pipework, the first question you are usually asked is what fluid are you handling? Ever wondered why you can’t just have a pump that is suitable for all fluids? This is where chemical compatibility comes into play.

So what is material compatibility?

Every material you can think of has its “kryptonite”; an opposite, something which when the material comes into contact with it, it suffers chemical attack and begins to decay. The actual impact of this depends on how resistant the material is with the medium it comes into contact with. Therefore, should a pump be pumping a liquid that it is incompatible with the material that it is constructed of, a problem arises.

The effects of chemical incompatibility

Broadly speaking there are 4 possible effects of chemical incompatibility:

Light Attack: Where the material suffers light etching and chemical attack to the surface which overtime can cause the surface to suffer pitting and general decay.

Swelling –Where the material absorbs the chemical and begins to increase in size. An example of this would be a Noryl impeller being used with diesel which swells and quickly becomes unusable as it catches against the casing and prevents the impeller from operating at full speed.

Brittleness –Where the material begins to harden and becomes brittle. An example of this is a gasket which when it becomes hard, loses its ability to expand and contract. A slight leak can occur on a pump as the gasket is unable to work according to the conditions and its design. If an operator notices the leak and tightens bolts, this will cause the gasket to break up.

Dissolving –Where the material simply dissolves in the chemical. An everyday example of this would be when sugar is added to hot water in tea or coffee, or salt in seawater. If a pump materials are not selected correctly then parts of the pump can dissolve.

I know what chemical I am pumping – it is bleach, can you help?

Once we know the chemical we are able select the most appropriate materials for the pump, but often more commonly brand names of chemicals are used rather than the actual chemical. An example of this is bleach which is akin to a vacuum cleaner being called a hoover – a brand name. Bleach is in fact sodium hypochlorite so it is this chemical we must check compatibility with.

Often fluids can be made up of various chemicals, different concentrations and even liquids where manufacturers refuse to reveal the chemicals used in their solutions as this is part of their formula. This of course makes it more difficult to check the fluid against the chemical pump materials. Usually we would request the Safety Data Sheet, also known an MSDS, to obtain full information on exactly what the fluid is.

How does a materials resistance change with temperature or chemical concentration?

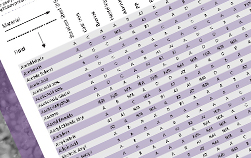

A material’s resistance to a chemical can change depending on the concentration of the chemical it comes in to contact, with as well as its temperature. For example Hastelloy C is compatible with Hydrochloric acid at 10% concentration at 20°C. However at 40°C, Hastelloy C has limited resistance. There are some concentrations which have the opposite affect; Hastelloy C is compatible with Sulphuric Acid at 98% concentration and up to 60°C, but at 80% Hastelloy C is only compatible up to 20°C. Only by being thorough can we guarantee that a chemical transfer pump will work with the chemical being pumped and provide a warranty.

Can we select a material based solely on its chemical compatibility?

In some cases yet, but in others there are more factors to bear in mind – it’s never straightforward!

There are some chemicals that crystallise when they come into contact with air such as varnishes or honey which can damage a pump’s seals. There are also chemicals which are flammable, or noxious all of which must be given careful consideration. There are also fluids which are non-lubricating which may be compatible with a material but would cause excessive wear.

I want a chemical pump to pump all chemicals, what can you do?

For all of the reasons above, we need the list of chemicals, concentrations and temperatures to check they are compatible. Without this information we cannot guarantee operation, and therefore any chemical transfer pump supplied would not be under warranty. It’s similar to going to a restaurant, saying you have an allergy to certain ingredients, but not confirming what you are allergic to and complaining when you have a reaction!

All of the above is combined with our technical knowledge, previous application experience and your application to select the pump which is right for you. If you have a specific query or application, you would like us to investigate please email sales@castlepumps.com or call 01773 533 283 where dedicated engineers are able to assist in selecting the most appropriate pump for your application.