Information Hub

Whether you buy, specify, maintain or operate pumps, you will find something useful to you in our Information Hub.

Pump Term Glossary

NPSH, Total Dynamic Head and Best Efficiency Point are just some of the terminologies used during the pump selection process, but do you what they mean? Technical jargon can sometimes leave your head in a bit of spin, so if you want to learn the lingo and understand what these words mean, let us guide you through 27 terms that you're likely to come across when buying a pump!

Pump Ordering Guide

With so many pump types, material options and performance specifications it can be difficult to ensure you are buying the right pump - and with factors such as application suitability and pump lifespan also to consider, the purchasing process can be even more difficult. So if you're unsure on the exact pump you require, use Castle Pumps 'pump ordering guide' to help you find a pump that meets your specific requirements.

Pump Specification Form

To make it as easy as possible for the customer, Castle Pumps have devised a pump specification form that prompts the user for the information required to specify a pumping solution that matches their requirements. Upon receipt of the form, Castle Pumps would devise a technical solution, which may include more than one offering, that would then be provided to the customer for verification.

Serial Numbers – The Fingerprints of the Pump World

When maintaining or replacing your existing pump, the first thing we will ask you is the model and serial number of your pump. Every pump is different, so by having the serial number it can quickly help them to locate the relevant information, therefore quickly helping you along with replacing an existing pump or sourcing spare parts. This guide will help you locate the necessary information!

The Importance of Low Shear Pumps When Handling Delicate Fluids

Are you pumping a shear sensitive fluid? Does your manufacturing process involve a liquid that alters when heavy force like stirring is applied? This article will give you more of an insight into exactly what a shear sensitive product is and how this impacts pump selection if your application involves handling one. Let’s start with a deeper look at the characteristics of a shear sensitive liquid…

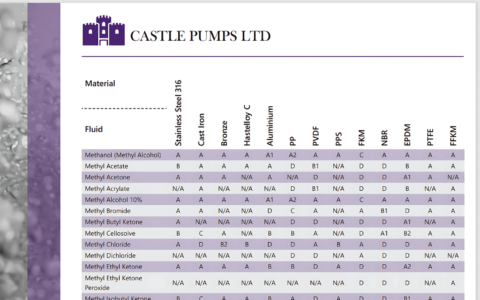

Fluid Compatibility Guide

Doing a fluid compatibility check when sourcing a pump is one of the first things you need to think about! Certain fluid/material combinations can result in corrosion, swelling, brittleness, leaking and even the dissolving of the pump! So ensuring you have the right pump material for the fluid you want, is a must! This fluid compatibility table will give you the information you need to determine which material will suit your fluid best.

Why Viscosity is Critical to Pump Selection

When specifying a pump for oil, we'll need to check what type of oil you'll be pumping. Viscosity is critical for pump selection, and with so many different types of oil it's no surprise that the range of viscosity can vary from oil to oil. Confirming the viscosity of the pumped medium will put you on track to getting the right pump for your application, and this article will explain in depth why knowing the viscosity is so important!

The Importance of Chemical Compatibility

Ever wondered why you can't just have a pump that's suitable for all fluids? Well this article will explain why, and it's all down to chemical compatibility! One of the first questions you'll be asked when sourcing a pump, fitting or pipework is 'what fluid are you handling?', and this is because the fluid will determine what material the pump needs to be made of to avoid corrosion, damage and failures!

Electric Barrel Pumps: 5 Reasons to Upgrade Your Manual Fluid Handling

Fluid handling in some production lines is still done by hand to save money. For example, a business making small batches of cooking sauce may transfer the liquid ingredients from one container to another by hand. This may be cost effective initially, but there are many reasons why using an electric drum pump would be more beneficial and cost effective in the long run than continuing to manually handle it.

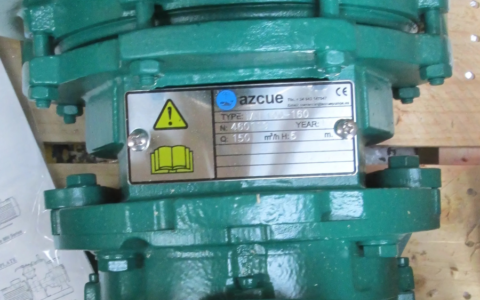

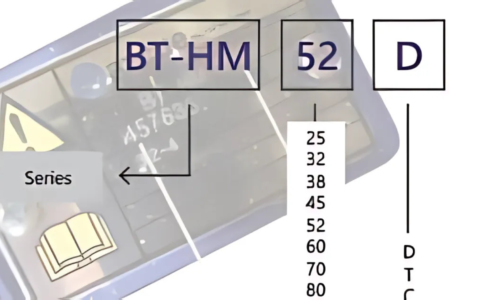

The Guide to Understanding Azcue Pump Model Numbers

A pump name plate and the letters and numbers on it can tell you a lot about a pump (if you know what to look for)! A combination of two letters will give you the pump type and a further two letters will let you know if an additional priming pump is present. Following this are a selection of numbers and letters and these will give you an insight into the pumps specifications. Find out more in this handy guide.

CAT Pump Spare Parts & Maintenance

With CAT Pumps built to offer efficient, long life performance it's vital that you keep up to date with maintenance and change spare parts when required. This guide to CAT pump maintenance and spare parts offers all the information you will need for servicing and replacing parts on your CAT pump, from what to look out for, how to locate model numbers and the typical schedule you should follow.

Pump Maintenance – Why, When and How!

Pumps are a key part of any industrial plant or factory and downtime of a pump can be costly. Therefore, it's important for pump maintenance to be carried out so that downtime can be limited. There are two classifications of pump maintenance; corrective and preventive. Despite corrective maintenance being a quick solution to a problem, it doesn't deal with preventing it from happening again, whereas preventive maintenance does.