Peristaltic Pump Guide

How do peristaltic pumps work?

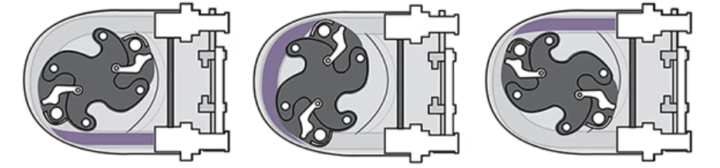

Peristaltic pumps are a type of rotary positive displacement pump that are made up of two integral components; a rotor that has a number of rollers or a “shoe” attached and a flexible internal hose/tube fitted inside a circular pump casing. It is for this reason, this pump technology is also referred to as a peristaltic hose pump. There are two different operating mechanisms of peristaltic pumps; roller and shoe operated, which we will now come on to.

Roller operated peristaltic pumps

As the rotor turns, the attached rollers compress the tube where the fluid is contained, and it is that action that forces the liquid from the pump's inlet to its outlet. As less friction is generated by the rollers in comparison to shoe designs, such peristaltic pump models have:

- Lower power consumption, with up to 30% energy savings compared to shoe peristaltic pumps

- Low starting torque - smoother operation and easier to adjust speed

- Easier hose maintenance as it doesn't require lubrication

Shoe operated peristaltic pumps

As the rotor turns, the attached shoe compresses the tube where the fluid contained, and it is this action that moves the liquid from the pump's inlet to its outlet. This version:

- Is ideal for more heavy duty, higher pressure requirements, where roller models can't efficiently handle the application.

- Have casings filled with lubricant to prevent abrasion of the exterior of the internal tube, which has to be maintained.

Design benefits

Variety of fluids – As the only part of the peristaltic tube pump that comes into contact with the pumped liquid is the flexible inner tube, only the material of the tube/hose needs to be compatible with the fluid rather than also having to consider the o rings, seals and valves. This makes it a versatile solution for many fluids by changing the material of the inner hose:

- Natural Rubber (NR) - For water based fluids

- Neoprene (CR) - Good balance between chemical and mechanical resistance.

- Nitrile (NBR) – For fats, fuels and oils.

- EPDM – Ideal for hot fluids and clean in place applications, acids and alkaline.

- Silicon (VMQ) - Best for very high temperatures

Leak-free – As the pumped liquid is kept contained within the inner hose, peristaltic pumps require no seal. The absence of a seal ensures that this pump type is less prone to leaking, making it an ideal solution for when handling corrosive liquids and dangerous chemicals, and where generally speaking a cleaner, safer operation is required.

Excellent solid handling and non clogging – As well as the above, peristaltic tube pumps are suited to heavy duty applications such as those involving viscous slurries and solids, as the fluid is only confined by the inner hose as there are no valves and seals to clog. This means that peristaltic pumps are able to handle solids and sharp and stringy particles without clogging up to the size of the diameter of the inner tube.

Low shear - Peristaltic pumps benefit from a gentle pumping motion and low rpm. As little shearing motion is applied by the pump, it does not alter the fluid's structure making the design ideal for handling delicate, shear sensitive fluids that are damaged by other pump types.

Reversible operation - This allows for tank to tank transfer i.e. filling and emptying applications, and the recovery of fluid from the hoses at the end of dispensing. This is particularly beneficial for peristaltic pumps used in mobile applications, where the hose is regularly removed in order to move the pump, to ensure liquid doesn't leak out the end.

Good suction lift and self priming capabilities - Peristaltic hose pumps can self prime up to 8m. They can also dry run indefinitely without damage in the event of the operator leaving the pump running, and can handle fluids with low moisture content.

Low maintenance – As the only wetted component of the peristaltic hose pump design is the inner tube, wearing parts are limited to just this and it is consequently the only part of the pump that needs to be maintained, which can be done quickly and easily. The absence of valves, seals and glands that can clog and wear when in contact with the pumped medium, particularly abrasive mediums, keeps maintenance time and spare parts costs down.

Typical applications of a peristaltic hose pump

Peristaltic pumps are the ideal solution for where other pumps fail. Their ability to handle highly viscous or solid laden mediums with no damage, their simple and low cost maintenance and their ability to dry run, makes them a popular choice for harsh and abrasive applications. In addition, the wide variety of materials that the inner tube is available in, along with the peristaltic hose pump’s seal-less design, means that even the most of aggressive fluids and chemicals can be handled.

Given the above design benefits, peristaltic tube pumps are ideal for the following (and many more!) high and low flow applications:

- Food and drink manufacturing

- Grout, cement, clay and mud transfer

- Sewage and sludge pumping

- Waste water and dewatering of excavations

- Oil sludge and waste oils

- Chemical dosing

- Paint, ink, pigment and dye

- Pulp and paper slurries

Does this sound like what you need?

If from reading the above it sounds as though a peristaltic pump is suits your industrial process application, take a look at our range of pumps