Customer: UK Oil Manufacturer

Application: Thermal oil pump for furnaces

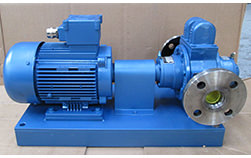

Equipment Supplied: Horizontal Vane Pump

Location: UK

Equipment supplied

1 x Bombas Trief Horizontal Vane Pump

- Model: BAL 12R

- Pumped fluid: Furnace Oil

- Installation: Horizontal

- Flow: 43 L/Min

- Discharge Head: 3 bar

- Max temperature: 250°C

- 0.55Kw 400V IP55 750rpm 50hz ATEX Motor

Enquiry

A UK oil manufacturer contacted us wanting a pump for transferring furnace oil from tanks to vehicles, which of course would be very high temperature. One of the main requirements of this thermal oil pump was to be able to clear the lines and dry run for short periods of time. The customer had already received a quote from an alternative supplier, but the lead time for them to get a suitable products was 6-7 weeks, which the customer really wanted to avoid waiting for.

Key challenges:

- Capable of handling high temperature fluids

- Able to dry run for short periods without damage

- Better the lead time of the competing quote

Solution

Given the high temperature, lubricating nature of furnace oil, we immediately knew our vane pumps would be an ideal solution, especially as they come with twin mechanical seals for added protection against high temperatures. The particular model of Bombas Trief vane pump we selected are also fitted as standard with duravanes, which automatically adjust clearances, whilst maintaining high levels of flow performance for a longer period of time compared to that of a standard vane.

To ensure that the pump would not sustain damage should the pump dry run as the customer needed it to, we specified it complete with a pressure relief valve.

As we could get the pump manufactured, ATEX approved for use in potentially flammable environments and delivered within 4 weeks of the order, the customer was extremely pleased to go ahead with our thermal oil pump offering.