Customer: Olive Oil Production Company

Application: Olive oil transfer

Location: Greece

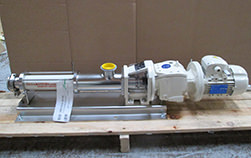

Equipment Supplied

1 x 0.75kw Progressive Cavity Pump

- Application: Transfer of olive oil containing crushed olives and olive stones

- Installation: Horizontal with inlet/outlet 2" TRI clamp

- Flow: 0.2m3/h

- Discharge pressure: 2 Bar

- Pump body: Stainless Steel 316

- Stator: NBR black food grade

- Voltage: 230V/400V

- RPM:1413 (Coaxial gearbox)

Enquiry

Castle Pumps received an enquiry from a new customer in the UK that was setting up an olive oil production line in Greece. They required a pump that could not only deal with the abrasive solids contained in the olives but also meet the food grade standard required.

Solution

Using our experience with food product transfer we knew a food grade progressive cavity pump would be perfect for this application. A progressive cavity pump is able to handle the solids and is also excellent at pumping shear sensitive products such as olive oil.

We worked closely with our progressive cavity pump manufacturer to select the most suitable pump. All areas of the pump that came into contact with the fluid had to be scrutinised to make sure the material used was fit for purpose. We selected 316L stainless steel for the casing and rotor and food grade NBR rubber was chosen for the stator. A specialised clamp was also fitted to minimise any areas that bacteria could congregate within the pump. The manufacturer adapted the pump to have a 2" TRI clamp Inlet/outlet connection due to the sanitary standards required.

The end product was a fully sanitary food grade pump mounted on a baseplate that was capable of handling soft solids up to 14mm and hard solids up to 7mm. This was manufactured and delivered to our customer within 4 working weeks.