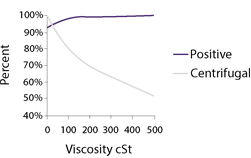

There are two main families of pumps; positive displacement and centrifugal (rotodynamic) pumps, both of which have their uses and best areas of application. It is important however to be able to identify when each pump type should be selected, which ultimately comes down to their working principle and the application at hand. This guide talks through those differences and gives examples of when one is more suited than the other.

Centrifugal pumps are one of the most popular pumping solutions in the world due to their highly efficient and simple design. However, different types of centrifugal pumps are best suited for specific applications. For example, for applications that require higher pressure capabilities, multistage centrifugal pumps are preferred over single-stage pumps. But how do you know which centrifugal pump type is best for your application? Read our pump guide and learn more

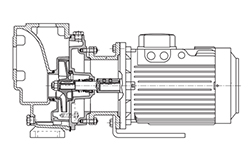

Submersible pumps are the easy option, but have you ever considered choosing a self-priming pump as an alternative? Self-priming pumps are often overlooked and sometimes not even considered in the first place, but these pumps have a number of advantages. We look at liquid handling, maintenance comparisons and differences in design, before summarising why we believe self-priming pumps to be a good alternative to submersible.

For applications involving the transfer of fuels, oils and other lubricating fluids, screw pumps and gear pumps are usually the pumping technology selected. Whilst a gear pump is a more than acceptable option for the handling of lubricating fluids, the design of the screw pump has several advantages over it.

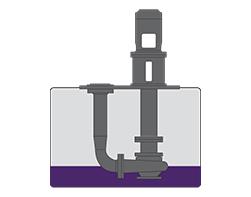

Vertical immersion pumps are a pumping technology with an elongated shaft encased in a column to separate the motor from the pump. Also known as vertical shaft or column pumps, they differ from submersible pumps because whilst their impellers are immersed in the fluid, the motor stays above it. These pumps have several design benefits which give it distinct uses compared to other pump types, and gives suitability for a variety of applications.

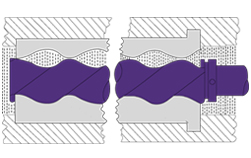

Progressive cavity pumps are a type of positive displacement pump known for their ability to handle viscous, shear sensitive and abrasive mediums at high pressures, with a smooth, low pulsating flow. Our progressing cavity pump guide includes technical information on the working principle of this pump type, benefits of the eccentric screw pump design and applications that the design is most suitable for.

Peristaltic pumps are a popular choice for applications where other pump types fail to meet the requirements i.e. highly viscous or solid laden mediums. In addition, the wide variety of materials that the inner tube is available in, along with the peristaltic hose pump’s seal-less design, means that even aggressive chemicals can be handled.

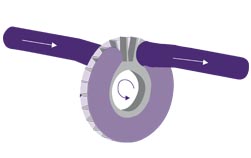

Rotary vanes pumps are part of the positive displacement pump family, designed for the transfer of clean low to medium viscosity fluids and fuels at relatively low pressures. Our sliding vane pump guide covers technical information concerning the mechanism by which the vane pump operates, advantages of the pump’s design and typical applications that vane pumps are often used for. Also included is a trouble shooting guide.

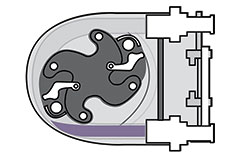

Flexible impeller pumps are a type of positive displacement pump, designed for the low pressure transfer, filling and dosing of a wide variety of fluids including shear sensitive and those containing solids. Our guide to the flexible vane pump design covers its working principle, benefits of the design and the applications that they are commonly used for. Also included is an impeller compatibility chart that determines the fluids each impeller type can be used with.

Side channel pumps have a working principle that is a middle ground between the two main pump families; centrifugal and positive displacement. They are designed for low flow, high pressure applications concerning low viscosity, clean fluids including those being handled at high temperatures and containing a level of gas. This guide provides information on the design benefits and applications that these pumps are suited to.

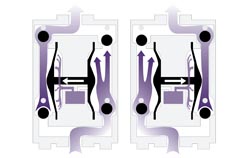

Air operated diaphragm or AODD pumps as they are also referred to as, are a type of reciprocating positive displacement pump that are powered by compressed air rather than an electric motor that most other pump designs are. They are a versatile design capable of handling low and high viscosity fluids, including those with solids and more aggressive chemicals. Read this guide for more information on their working principle.

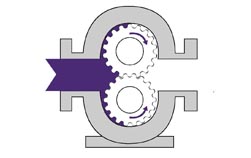

Gear pumps are one of the most popular types of positive displacement pump; with internal and external variations. They are commonly used for the transfer of high viscosity oils and other lubricating fluids at relatively high pressures. This guide gives a detailed insight into the working principle of both external and internal gear pumps and the applications they are typically chosen for.

Generally speaking, pumps can be divided into mechanically sealed pumps and seal-less magnetic drive pumps. Although mechanically sealed pumps are usually a very popular choice, there are some key benefits seal-lees magnetically coupled pumps have over the traditional mechanical seals. This guide gives a detailed insight into the mag drive design benefits, potential drawbacks, and the typically chosen applications.

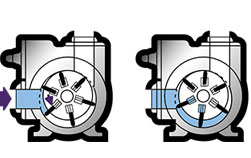

Due to their relative simplicity of design, centrifugal pumps are the most common pump type in the market. Centrifugal pumps are categorised into either single or multistage pumps, both of which have their uses. What is important to understand is where which should be selected, which ultimately comes down to their working principle and the application in question.

Castle Pumps are fully accredited to enable you to buy with confidence. Our accreditation includes:

![]() A division of the CTS Group, Part of Flow Max Ltd.

A division of the CTS Group, Part of Flow Max Ltd.