| Max Flow Rate | 81.66lpm |

| Max Head | 150M |

| Inlet/Outlet | 1 1/2" |

| Solids Size | 40mm |

| Max Flow Rate | 81.66lpm |

| Max Head | 150M |

| Inlet/Outlet | 1 1/2" |

| Solids Size | 40mm |

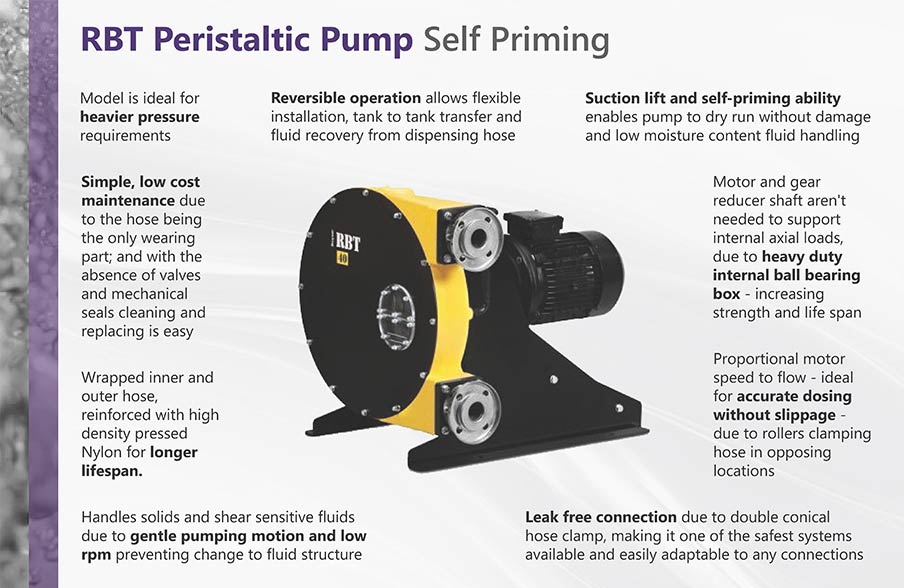

The Boyser RBT-40 Series Peristaltic Pump is the largest of our hose pumps, with the highest performance capabilities in the range. Its rugged design makes this self priming peristaltic pump extremely heavy duty and capable of efficient operation in the harshest of environments where other pumps fail due to issues such as dry running damage, clogged valves and seal failures.

One of the largest benefits of the peristaltic hose pump design is that the hose is the only wearing part, which is easy to clean and replace, making it simple and low cost to maintain relative to other pumping technologies. Thanks to its internal hose being available in a variety of materials, its ability to handle solids, fluids with little moisture and shear sensitive mediums these Boyser pumps are extremely versatile. The wide range of applications that it is suitable for include oily sludge, bilge water, oils, shear sensitive liquids, slurries with solids present, dewatering, drainage of tanks, emergency pump leakages, food stuffs, acids, lime milk and muds.

As a shoe operated peristaltic hose pump rather than a roller operated one, the Boyser RBT is capable of higher pressures than other peristaltic pumps on the market, making them suitable for pumping viscous fluid long distances.

| Inline Pulsation Dampener | Ensures a continuous, smooth flow for the accurate use of flow meters and pressure switches. By eliminating vibrations and hammering, operation is relatively quiet and working life is increased. |

| Hose Leakage Sensor | Should the only wearing part of the pump (the hose) fail, the sensor can shut off the pump or activate an alarm to allow the situation to be addressed quickly. This makes the pump ideal for remote installations or where hazardous fluids are handled. |

| Vacuum Assisted Priming | Improves the pump's self-priming capability in installations involving particularly viscous fluids or difficult suction conditions. |

| Halar (ECTFE) Coating | Improves the corrosion resistance of the pump in chemical or other hazardous applications. |

| PP/PDV Connections | As standard, connections are Stainless Steel, but for chemical applications they can be supplied in alternative materials. |

| Integrated Control Panel | Can be configured as per the user requirements with features such as on/off, speed control, reversing switch, flow and pressure display, leakage warning. |

| Trolley or Base Plate | For the flexibility of installation and enhanced mobility where required. |

| Inverter | Pump speed can be slowed down to the required flow, extending the life span of the motor by not making is unnecessarily work to full capacity, and reducing wasted energy costs. |

| Feed Screw & Hopper | For the pumping of highly viscous fluids that don't flow with ease and are prone to breakages. |

The Boyser RBT Series Peristaltic Hose Pumps are available with the following material options:

| NR | NBR | EPDM | NR-A | NBR-A | Hypalon | |

| Hose | X | X | X | X | X | X |

The Bosyer RBT peristaltic pump are the ideal solutions for applications where typically, other pumping technologies fail. The following benefits make peristaltic pumps ideal for heavy duty site applications, various chemicals and process liquids and abrasive and viscous slurries.

Peristaltic hose pumps are able to handle highly viscous, dry and solid laden mediums with no damage, making them a popular choice for harsh and abrasive applications. In addition, the wide variety of materials that the inner tube is available in, along with the peristaltic hose pump’s seal-less design, means that even the most of aggressive fluids and chemicals can be handled. This makes the RBT peristaltic pump ideal for applications including:

| Marine Applications | Industrial Applications |

|

|

Castle Pumps are fully accredited to enable you to buy with confidence. Our accreditation includes:

![]() A division of the CTS Group, Part of Flow Max Ltd.

A division of the CTS Group, Part of Flow Max Ltd.