We received an enquiry from a contract winemaker based in the UK. They required a food grade pump to transfer wine at temperatures between 2 and 65⁰C, with a maximum flow rate of 15,000 litres per hour and ideally the option of variable speed to enable more control. Due to the nature of their application and the specifications required, we supplied the Liverani All in One Flexible Impeller Pump which was a perfect fit for their requirements.

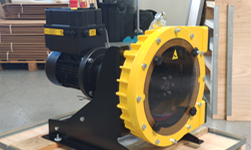

We received an enquiry from a food waste management company looking to pump a caking mix of bran and water. The viscous nature of this fluid meant that the pump technology chosen needed to be carefully selected to ensure no clogging, damage or running problems. Our experience allowed us to pick a peristaltic pump able to do just this.

Castle Pumps received an enquiry from an apple grower which supplies worldwide cider manufacturers with apple juice from concentrate. They required a pump to transfer small quantities of juice at a time, but was unsure of the fluid's viscosity. Using our experience we were able to determine the viscosity through asking a number of questions, and were therefore able to provide our food grade solution suitable for their needs.

We received an enquiry from this brewery company in Scotland who required a portable hygienic pump for the transfer of beer within their factory. We decided the best option would be a food grade flexible impeller pump with tri-clamp connections in order to meet the necessary standards within the food industry. The customer was that happy with their pump that they sent us some beers to show us what the pump would be helping to produce.

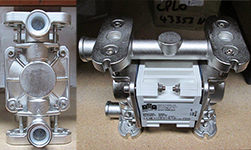

This customer was having daily issues with a pump brought from another supplier. The pump, which was transferring blood, water and feathers; was clogging every day, halting production and costing them £0000's in downtime. We decided to visit the site to get a greater understanding of the customer's requirements. From there, we came up with a pumping solution fit for purpose, which has been running for over 3 months (& counting) clog free.

As well as pumps for industrial and marine applications, Castle Pumps can also supply pumps for the food grade market. This was a new customer that was enquiring about a pump to transfer Spaghetti Bolognese from production to packaging when hot. Castle Pumps visited site to get as much information as possible, and by using our extensive knowledge and past experience we were able to design a bespoke pump kit and supply all within five working weeks.

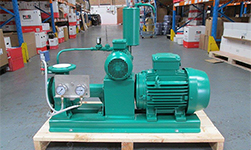

Castle Pumps receive a wide range of enquiries for a number of industry applications. Farming fish on land is an unusual but increasing market which Castle Pumps have adapted to in order to specify and supply pumps for requirements posed for within this market. A centrifugal pump was selected to match their requirements, which was fitted with accessories and a bespoke control panel to ensure all of their specifications were met.

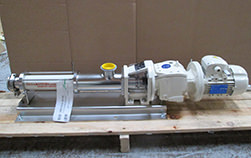

Castle Pumps understand that in situations involving products for human consumption, hygiene is the most important factor to focus on. We chose a progressive cavity pump which is ideal for the pumping of shear sensitive products such as olive oil, as well as it's ability to handle abrasive solids. After carefully selecting the most appropriate materials to modify the pump, it was delivered to our customer within four workings weeks from the initial enquiry.

Castle Pumps are fully accredited to enable you to buy with confidence. Our accreditation includes:

![]() A division of the CTS Group, Part of Flow Max Ltd.

A division of the CTS Group, Part of Flow Max Ltd.