Reverse Osmosis Pumps

Reverse osmosis (RO) is a filtration process that separates pure water from the dissolved impurities and waste matter within it. To understand the role that reverse osmosis pumps play, it is important to understand what exactly it is and how the process works…

What is Reverse Osmosis or RO?

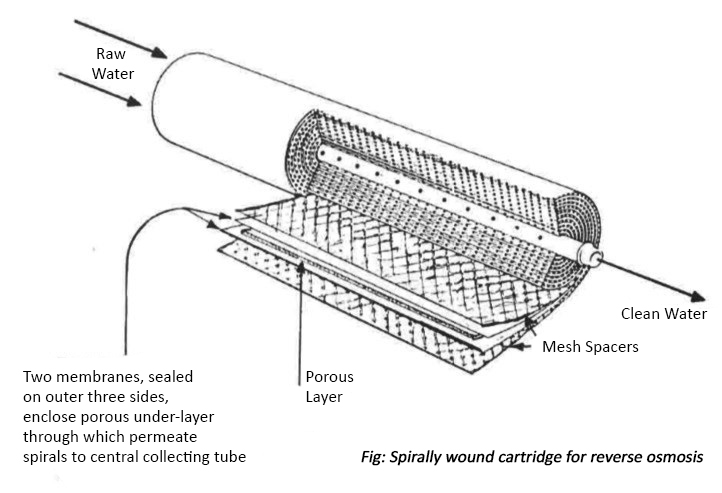

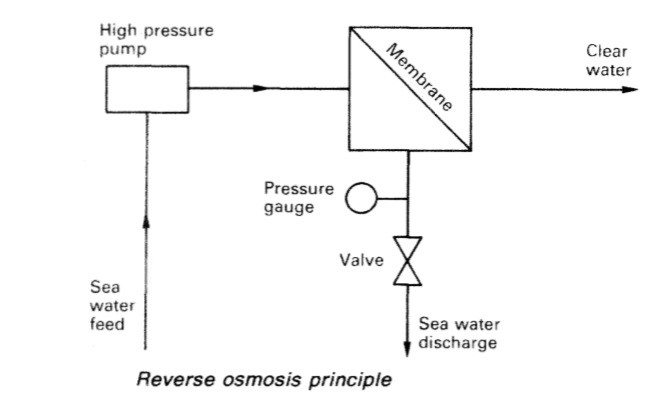

As you can see in the below simplified diagram, a reverse osmosis system works by forcing the water through a semi-permeable membrane at a pressure high enough to overcome the natural osmotic pressure. To achieve the required force, the system uses a high-pressure RO pump. The membrane then acts as a porous sheet barrier, with pores only small enough to pass pure water through, whilst rejecting larger molecules such as the dissolved salts, minerals, bacteria and other particles.

What the process of reverse osmosis leaves is highly purified water for future use and a concentrated waste to be discharged of. So that’s the science behind it, but why and when is reverse osmosis used and how does this impact the pumps chosen…

Reverse Osmosis Water Pump Applications

High-pressure capabilities are the most vital feature of reverse osmosis pumps to ensure they exceed natural osmotic pressures. Typically, single stage centrifugal pumps, whilst most popular for water-based applications, do not reach the pressure requirements for reverse osmosis. For this reason, typical pumping technologies utilised for such processes are triplex piston pumps, multistage pumps and side channel pumps. Whilst pressure is one necessity, the different uses of reverse osmosis will result in further requirements of the RO pump…

- Desalination - One of the widest spread uses of reverse osmosis is desalination. Desalination is the removal of salts, minerals and ions from seawater to convert it into fresh water for drinking, washing and other uses. Brackish water reverse osmosis is the same process, but for water with lower salt content than sea water, such as that from rivers and estuaries.

Most modern vessels are installed with a seawater reverse osmosis system to produce fresh water onboard using the water most easily accessible to them, which saves the vessel owner from the costs of purchasing water from suppliers at each docking port. In countries and cities where there are water shortages, the Middle East, Cape Town and California being amongst them, desalination plants have been built on land to help provide fresh water supplies for drinking or irrigation during periods of drought.

Desalination pumps are usually constructed of materials such as bronze and stainless steel as these are resistant against the corrosive salt content. The level of salt content in the water being desalinated also impacts the pressure requirements, meaning sea water reverse osmosis pumps need higher pressure levels than the desalination pumps used for brackish waters.

- Industrial wastewater treatment - Lots of industrial processes involved in manufacturing and the cooling of plant and machinery make use of water, which when finished with ends up containing chemicals, oils and other residues. By using reverse osmosis, the often harmful waste products can be separated from the clean water for safe disposal. The clean water can them be reused, saving the company money on water bills.

Depending on the nature of the wastewater in question, there may be different requirements of the reverse osmosis water pump. For example, in the recycling industry, harsh chemicals are used to treat any metals. As the wastewater produced is particularly harmful, the RO pump in question needs to be able to deal with such corrosive fluids, which will in turn affects its materials of construction.

- Food and drink industry - Reverse osmosis is also used in various food production processing. For example, it is used in the dairy industry to separate whey from water to leave concentrated whey protein, and also in maple syrup production to remove water from the sap before it is boiled down to form the syrup.

When this is the case the reverse osmosis water pump may need to be food grade depending upon at what part of the manufacturing process it takes place.

Reverse Osmosis Pump Case Studies

Below is an examples of a project where we supplied a reverse osmosis pump to a marine customer.