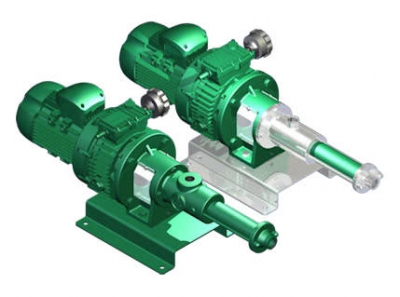

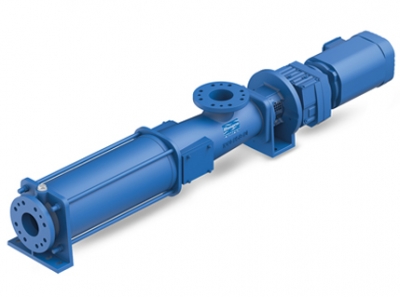

Progressive cavity pumps are a type of positive displacement pump, also referred to as a helical rotor pump, a mono pump or an eccentric screw pump. Thanks to their ability to handle viscous fluids, slurries, liquids that contain large particles, gas-liquid mixtures and sheer sensitive fluids, the progressing cavity pump is a popular type of pump for potentially tough applications when other pumps may fail. Read our progressive cavity mono pump guide here.

Applications in which eccentric screw pumps are used include, but are by no means limited to:

Oil transfer

Sewage and sludge pumping

Waste water treatment

Bilge water removal

Viscous chemical pumping

Biomass Plants

Progressing cavity pumps have good suction lift capabilities as they have a much lower NPSH. For example, they have suction lift of up to 8.5m, even when the pumped medium is a gas-liquid mixture. As well as having great suction capabilities, helical rotor pumps are also capable of dealing with high pressure applications, making them ideal for pumping viscous fluids over large distances. The progressive cavity pump design means that it benefits from steady, low-pulsation pumping. This ensures that in dosing applications, extremely accurate metering can occur without the need for an additional valve. In addition, a mono pump can maintain the same flow rate regardless of the fluid viscosity; making it ideal in an application where the liquid viscosity is variable.