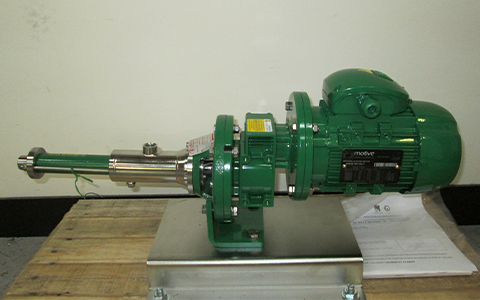

Nova Rotors DM-JM Progressive Cavity Dosing Pump

Dosing Pump & Water Treatment Pump

| Key Specifications | |

|---|---|

| Max Flow Rate | 45lpm |

| Max Head | 240M |

| Max Temperature | 150°C |

| Max Viscosity | 1,000,000 cP |

| Solids | 3mm |

| Size | 3/8" |

The Nova Rotors DM-JM series are progressive-cavity pumps commonly used as dosing pumps due to their constant, precise flow output. These models have superseded the old Nova Rotors MN dosing pumps. The design of this progressing cavity enables pumping dense, viscous fluids containing solids at very small, precise flow rates. The DM series of helical rotor pump is also excellent at handling shear sensitive fluids; this is due to the fact that the pump generates low pulsations, so there is less agitation caused to the pumped medium. Frequent applications of this Nova Rotor mono pump include oily sludge transfer, bilge water transfer, sewage transfer, bio-waste and alcohol transfer.

This dosing pump is also available as a food-grade progressing cavity pump constructed from polished stainless steel 316 and a food grade stator. Typical food transfer pump applications include fruit juice pulp, beer, fruit paste, grapes, grape paste, wine and edible oils.

To understand how progressive cavity pumps work and which applications they are best suited for, read our detailed progressive cavity pump guide.

Key features & performance benefits

• Low pulsation flow – ideal for shear-sensitive fluids, as it does not change the fluid state

• No vibration – smooth, stable operation with reduced mechanical wear

• High self-priming capability – excellent suction and reliable start-up

• Reversible flow – can pump in both directions for flexible system design

• Precise and accurate metering – consistent flow rates for dosing applications

• Solids handling – capable of pumping fluids containing suspended solids

• Handles very viscous media – suitable for fluids up to 1,000,000 cP

• Compact and lightweight – easy to install in confined spaces

• Double mechanical seal option – improved leak protection and durability

• Motor options – 230V and three-phase 50Hz / 60Hz available

• Food-grade construction – FDA-approved materials for hygienic applications

• Marine certification available – suitable for marine and offshore use

The Nova Rotors DM progressive cavity pumps are available with the following material options:

Lubrication Dosing for Decking Manufacturer - Progressive Cavity Pump

Castle Pumps pride themselves on being able to specify and design solutions to meet individual customer needs. This case study demonstrates this, where in order to meet the adjustable flow rate requirements of dripping lubricants onto wood fibres, Castle Pumps ensured that a motor variator was added to the unit to control the speed of the pump.

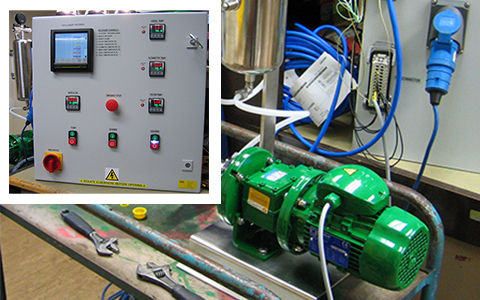

Fuel & Coal Dust Slurry for R&D - Progressive Cavity Pump

A new customer approached us that needed a pump for an abrasive slurry of fuel oil and coal dust. The pump needed a low flow rate and the ability to handle abrasive coal dust, whilst also needing to be controlled by a variable speed drive for testing purposes. We supplied a progressing cavity pump as its properties and capabilities were the best match for the requirements, as it is this type of pump is really good when handling solids or abrasive liquids.

FAQs

It consists of a spiralled helical rotor (like a cork screw) that sits tightly inside a rubber stator/sleeve. As the rotor turns inside the stator, it forms a set of fixed-shaped cavities that progress along the length of the stator and force the fluid inside to move along with them as they turn.

Their pressure capabilities and viscosity handling is unrivalled, which means that whilst they are quite expensive in design and large in footprint, they are often selected for applications when all other pumping technologies will fail.

The design is best suited to highly viscous and lubricating fluids including oils, sludges, waste matter, biomass, pastes and grape pressing that may contain very large solids, as well as pumping viscous products over long distances.

Yes! A progressive cavity pump's tight tolerances mean it has excellent suction capabilities.

Yes they have excellent solid handling capabilities! However, it should be noted that abrasive fluids e.g. low viscosity/water based fluids containing solids may cause shorter stator wear.

Our progressing cavity pumps can be supplied with auger feed allowing non-flowing mediums such as dry sludge and waste matter to be pumped without clogging. We can also provide liquid injection ports which are popular when liquid waste is added to dry content waste to allow it to flow.

No! Even short period of dry running can result in damange to the rotor and stator, making dry run protection a must if there is risk of this.