The Liverani GR Flexible Impeller Pumps are a range of belt driven models, able to handle a wide variety of fluids. This is a cost effective means of operating the flexible vane pumps at different speeds without the use of an expensive gearbox. Furthermore, when using GR flexible vane pumps on viscous or solids laden fluids the belt drive will protect the motor from overloading by slipping, therefore avoiding potentially lengthy and costly downtime.

Flexible impeller pumps are a very versatile in the applications that are suitable for thanks to several design benefits. Firstly, thanks to their supple vanes they are able to handle not only clean, light fluids, but also viscous, solid laden slurries. Secondly, the multiple materials the impellers are made out of mean they are compatible with many fluids e.g. NBR for fats and fuels, EPDM for chemicals and hot fluids and natural rubber for water based liquids. Flexible vane pumps with EPDM and NBR impellers are able to be supplied with FDA Certification, making them a popular electric food grade pump solution. Their low shear operation also makes the ideal for handling delicate fluids that can be altered by other pump designs.

Flexible impeller pumps are renowned for their dry self-priming capability, making them ideal for applications where good suction lift capacity is needed such as the emptying of tanks, sumps and other containers. The GR flexible vane pumps are widely used in transferring, filling & emptying applications, but when used in conjunction with a carrying handle and their integral on/off reversing switch they are also a very reliable utility pump solution popular for tank to tank transfer.

For more information on the design of flexible vane pumps and how they operate, read our guide.

Features of the GR Series Flexible Vane Pump:

- Belt driven flexible impeller pump

- Gentle, pulsation free pumping mechanism ensures the handling of shear sensitive liquids.

- Solids passage capability - 10mm (MINOR), 15mm (MAJOR), 25mm (MAXI)

- Dry self priming up to 6m without the need of a non return valve.

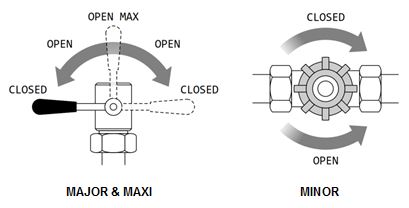

- Pumps can be operated in either direction via a reversing switch mounted on the pump.

- Specific models are available with 2 speed operation, controllable via a rocker switch on the terminal box.

- Pump head can be rotated and installed in a range of positions for versatility.

- Wide range of connection types available including DIN, BSP Male & Female, Triclover, SMS, RJT, Friederich, Garolla, and Macron

- Optional Stainless Steel AISI 304 Pipe Fittings for easy installation of the pump into existing pipework

- Flexible vane pump heads are SS304 as standard. SS 316 available on request,

- NOTE: units are supplied with Garolla connections as standard with hose fittings, clamps and seals included.

- Unit can be supplied with or without a control panel as well as fitted with dry-run protection .

- Manual by-passes (MAJOR & MAXI) for manual adjustment of the flexible impeller pump capacity available on request.

- Automatic barrel filling kits are available complete with stainless steel nozzle, non return valve & pressure switch.

- Accessories include inverter drive for variable speed operation, dry run protection, pressure switch for automatic pumping, level sensors, remote control & radio operation.

- Spring loaded by-pass for the MINOR for manual adjustment of the capacity and use with a nozzle.

- GR MINOR 40 – 1.5Kw, 1-3 phase 230-400v, single speed operation. 300 rpm. Max Flow 2150 L/h, max head 16M.

- GR MINOR 40 – 1.5Kw, 1-3 phase 230-400v, single speed operation. 470 rpm. Max Flow 3300 L/h, max head 18M.

- GR MINOR 40 - 1.5Kw, 1-3 phase 230-400v, single speed operation. 700 rpm. Max Flow 4700 L/h, max head 20M.

- GR MINOR 40 - 1.6Kw, 3 phase 230-400v, 2 speed operation. 470 rpm. Max Flow 3300 L/h, max head 18M.

- GR MINOR 40 – 0.9Kw, 3 phase 230-400v, 2 speed operation. 235 rpm. Max Flow 1600 L/h, max head 12M.

- GR MINOR 40 – 2.2Kw, 3 phase 230-400v, 2 speed operation. 700 rpm. Max Flow 4700 L/h, max head 20M.

- GR MINOR 40 – 1.5Kw, 3 phase 230-400v, 2 speed operation. 350 rpm. Max Flow 2500 L/h, max head 16M.

- GR MAJOR 60 – 1.5Kw, 1-3 phase 230-400v, single speed operation. 470 rpm. Max Flow 10500 L/h, max head 12M.

- GR MAJOR 60 – 1.86Kw, 3 phase 230-400v, single speed operation. 700 rpm. Max Flow 15000 L/h, max head 16M.

- GR MAJOR 60 – 0.9Kw, 3 phase 230-400v, 2 speed operation. 235 rpm. Max Flow 5100 L/h, max head 8M.

- GR MAJOR 60 – 2.2Kw, 3 phase 230-400v, 2 speed operation. 700 rpm. Max Flow 15000 L/h, max head 16M.

- GR MAJOR 60 – 1.5Kw, 3 phase 230-400v, 2 speed operation. 350 rpm. Max Flow 7800 L/h, max head 12M.

- GR MAXI 80 - 4Kw, 3 phase 230-400v, single speed operation. 470 rpm. Max Flow 34200 L/h, max head 16M.

- GR MAXI 80 - 4Kw, 3 phase 230-400v, single speed operation. 600 rpm. Max Flow 41400 L/h, max head 16M.

Material options for the GR flexible impeller sanitary pump:

| Description | Stainless Steel AISI 304 | Stainless Steel AISI 316 | Nitrile (NBR) | Natural Rubber (NR) | Neoprene (CR) | EPDM | Silicon (VMQ) | St. St. / Graphite / NBR | Tungsten Carbide / NBR | Tungsten Carbide / Viton |

| Part List | | | | | | | | | | |

| Pump Body | X | X | | | | | | | | |

| Impeller | | | X | X | X | X | X | | | |

| Mechanical Seal | | | | | | | | X | X | X |

** NOTES

1.Changes in Mechanical Seal Materials are at cost. All pumps are supplied with Ceramic / Graphite / NBR as standard.

2.Changes in Impeller Materials are Free of Charge. All pumps are supplied with Natural Rubber Impellers as standard.

3. EPDM and NBR impellers are available with FDA certification

The beauty of the GR flexible impeller pump is it's versatility. Thanks to the following features it is an option that can be applied to many application requirements.

- Handles solids up to 25mm – Supple impellers bend to pass viscous fluids and slurries up to 50,000 CP and solids without damage to the pump

- Applies low shear – Ideal for delicate, shear sensitive fluids that can be damaged or altered by other pump types such as cream that gets thicker when whipped.

- Reversible operation – Allows cleaning solution to be ran through after use for hygienic pump applications, and tank to tank transfer applications.

- FDA approved – EPDM and NBR impellers with FDA certification for food grade pump assurance. Stainless sanitary enclosures and Tri-clamp couplings available.

- Smooth, steady pumping – Provides a consistent flow ideal for dosing ingredients, chemicals and process fluids and filling finished product into packaging.

- Self-priming up to 6m – Enables the emptying of tanks and drums without a non-return valve or regular manual priming being required.

- Various mounting positions - Allows for versatile installation to fit the pipework at hand

- Various accessories available - Trolley for portability, bypass valve for nozzle dispensing, control panel, variable speed drive, level sensors and dry run protection

Flexible impeller pumps are a versatile design of pump for relatively low pressure applications, mainly with thanks to their impellers being produced in a wide range of materials for fluid compatibility including food grade applications. As the impellers are made of a supple, rubber type material that is able to bend, flexible vane pumps are also able to handle viscous fluids and those with solid content without causing damage. They also apply little shear to the pumped medium, making them suitable for shear sensitive fluids and their ability to be operated in reverse makes them ideal for tank to tank transfer. These design benefits make them suited to many applications including:

|

Marine Applications

|

Industrial Applications

|

- Contaminated bilge water pumping

- Oil and lubricant transfer

- Black and grey water pump

- Sludge and slurries

- Fish waste pump

- Tank to tank seawater transfer

|

- Food processing and transfer

- Dairy products

- Brewery and distilleries

- Chemical pumping

- Waster water pump containing solids

- Oil and lubricants

- Viscous fluids, sludges and slurries

- Soaps, creams and gels

- Paints, glues and detergents

|

![]() A division of the CTS Group, Part of Flow Max Ltd.

A division of the CTS Group, Part of Flow Max Ltd.