Castle Pumps received an enquiry from a regular maritime logistics customer who has over 90 vessels - a lot of which have Azcue pumps installed onboard. One of their tug supply vessels needed to replace some existing seawater cooling pumps for the onboard air conditioning system. We supplied some vertical inline pumps suitable for use with seawater and which matched their existing dimensions and performance requirements.

Castle Pumps received an enquiry from a new customer who needed to upgrade their ballast water system, in order to meet the 'Ballast Water Management Convention 2017' regulation. We supplied Azcue cast bronze pumps to ensure that all wetted parts that come into contact with the seawater are non-ferrous and therefore would not corrode.

Castle Pumps are committed to providing the best possible support and service to customers, so when an emergency pump is required, we strive to provide one in a preferable time frame. An enquiry for an emergency replacement pump was received after hours on a Friday, needed for installation Monday morning whilst the vessel docked. By working out of hours and supplying from our 'from stock' range, we were able to deliver on time.

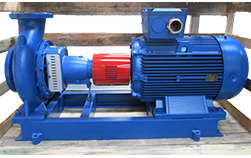

Here at Castle Pumps we understand that timing is important within the marine and offshore market. Quite often we receive enquiries that need to be dealt with quickly in order for the purchase and delivery to follow suit and minimise lead time. This subsea oil and gas company needed five sea water cooling pumps on a quick lead time. For this customer, we provided five long coupled centrifugal pumps in less than five weeks.

Some of the enquiries we receive here at Castle Pumps are straight forward and give us all the information that we need to specify a pump. This fishery company enquired asking us for a specific type of pump and told us the exact fluid and contents that they'd be pumping. This information enabled us to proceed quickly with our recommendation and then onto the manufacture and supply of the pumps.

Castle Pumps receive a wide range of enquiries for a number of industry applications. Farming fish on land is an unusual but increasing market which Castle Pumps have adapted to in order to specify and supply pumps for requirements posed for within this market. A centrifugal pump was selected to match their requirements, which was fitted with accessories and a bespoke control panel to ensure all of their specifications were met.

Castle Pumps have been specifying and supplying pumps for the marine market for several years, and therefore have expertise and knowledge when it comes to marine enquiries. The world's largest container ship in 2012 contacted Castle with an urgent enquiry, requiring two boiler feed pumps. Castle Pumps were able to select a model that matched their requirements and dispatch them in just 9 working days!

Castle Pumps understand that the selection process of a pump is the most important part of the buying procedure, so ensuring that we gather the correct information is vital. This information ensures that the customer will get a pump that works, and a pump that's efficient in saving money in both power and spares over it's lifetime. By collecting the necessary information we were able to spec and source the best pump for this customer's needs.

Castle Pumps have established a network of manufacturers that they can rely on when they require bespoke or tailored pumping solutions. The customer in this case study required a replacement pump that could be directly installed into existing pipework. Castle Pumps were able to get a pump specially manufactured to match the dimensions of the existing pump, therefore eliminating the need to adapt the installation.

Castle Pumps understand that for some companies the lead time on wearing parts is one of the most important factors, and therefore ensuring access to local stock is vital. In this example, we were able to improve on the previous supplier's lead time on spare parts by three weeks. As pump downtime for a dredging company is very costly, the customer was hugely impressed with our service.

An engineering company who were refurbishing a leisure yacht needed pumps for the sewage and oily waste water tanks, but were having trouble sourcing surface mounted self-priming pumps that would fit into the allocated space, that would perform the required duties. Castle Pumps came up with a solution and provided them with a unique range of progressive cavity pumps that matched their requirements and delivered them to the engineers in just over four weeks.

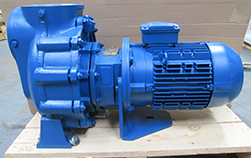

This UK based Marine Dredging company required a self-priming centrifugal pump, in cast iron to save costs, for transferring sea water containing small amounts of sand. We selected a horizontal self-priming centrifugal pump with a cast iron casing and bronze impeller from our CA range, capable of allowing 10% passage of sand content in the sea water.

A UK ferry operator required a verticle inline screw pump with Lloyds approval, due to undergoing a marine gas oil conversion. The customer needed the pump in 3-4 weeks in order to meet the vessels dry docking program. Castle Pumps supplied a vertical inline screw pump in just over 3 weeks, complete with marine certification. In result of our quick response and supplying the pump within the time needed, we were also asked to supply a DN80 strainer and flowmeter suitable for MGO.

An offshore engineering company required a surface mounted pump which could pump kerosene. The customer had some budget restraints which we needed to review. Due to these constraints, we supplied the centrifugal pump in a low cost material, with an explosion proof motor - making it perfect to handle kerosene. The customer was happy with the finished product and it was delivered to them in Nigeria within 10 working weeks.

This existing customer needed to upgrade their fire pump system on board their vessel and decided to contact us due to our reliability with past projects we have done for them. Due to the extensive knowledge and experience we have on the marine sector, Castle Pumps were able to meet the customers specific requirements and provide them with an ideal pump which was manufactured and marine certified in fewer than 8 working weeks.

This customer needed to purchase various pumps for a fuelling station that they were building off the coast of Malta. The pumps needed were to transfer kerosene, diesel and petrol from storage tanks at the fuelling station, to the boats being refuelled. With this, as well as other factors, Castle Pumps were able to supply centrifugal pumps that matched their requirements and budget, and were delivered within 10 working weeks to the customer.

A private boat owner was installing a reverse osmosis system aboard their vessel and required a high pressure pump for the system to convert sea water into fresh water - at a duty of 8.8 L/min at 35 Bar. Due to our wealth of experience with reverse osmosis systems; we were able to select a plunger pump that matched their requirements.

Castle Pumps have scores of experience supplying pump solutions to the marine industry. An existing customer contacted us with a new enquiry for a solids handling sea water pump, which needed to be less costly and have better lead times than existing pumps. We offered and supplied a non-clogging centrifugal pump with a vortex impeller, which can handle solids as large as the discharge diameter. Minimal modifications were needed to their existing system and lead time and price were improved greatly.

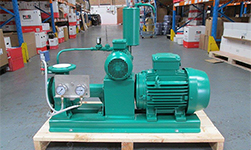

Castle Pumps not only supply individual pumps, but also complete pump packages including ancillary items. The customer needed a portable, self priming, variable speed water supply pump package which could be powered by the clients vessel whilst in a dry dock. By designing, building, testing and supplying the customer with the pump package, it enabled the vessel to be completely autonomous in the supply of fire water, AC and refrigeration services.

Castle Pumps have a wealth of experience supplying pumps to the marine industry, and we ensure that we match the features of the pump to the specific application at hand. This case study demonstrates this, as we knew that for guaranteed reliability for emptying a sump of sea water and waste solids, a pump with vortex non-clogging impellers would be required and the material would be best in bronze to avoid corrosion from the sea water.

Castle Pumps customise and engineer pumping solutions when required, to ensure that they match the customer's bespoke requirements exactly. In this case study, we put together a ready to use skid mounted pump system complete with pump, motor, belt drive, guard and steel base to meet their requirement for a high pressure, low flow solution.

Castle Pumps have a lot of experience in the marine industry including specifying and supplying pumps that are to be used on board new ships. Like in this example, where a screw pump was supplied to an asphalt carrier as a cargo booster pump, specifications often change when supplying a new build which makes the project more complex.

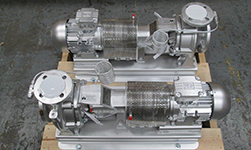

Castle Pumps pride themselves on being as flexible as possible to ensure that they meet the client's requirements. In this example, the customer required a pump with a range of features including ATEX motors, dry run protection and variable speed drives. On top of this, the pump needed to be supplied with counter flanges for immediate installation and supplied within a reasonable time frame; all of which were delivered.

Castle Pumps have built solid relationships with many industrial pump manufacturers, which gives us confidence in our ability to meet tight project time scales. This case study illustrates this, where we were able to get two ballast pumps manufactured and marine certified in three weeks less than the industry standard lead time.

Castle Pumps are fully accredited to enable you to buy with confidence. Our accreditation includes:

![]() A division of the CTS Group, Part of Flow Max Ltd.

A division of the CTS Group, Part of Flow Max Ltd.