Castle Pumps received an enquiry from one of the largest frozen food manufacturer brands in the UK that needed a replacement chemical pump for cleaning the processing plant and equipment. Due to the air supply being already available on-side and reliability being key, we specified Debem Boxer 50 AOOD pump. We carefully selected all pump elements to ensure they are compatible with the cleaning chemical and handle the hazardous application.

We received an enquiry from a new customer who makes electronic diagnostic machines for healthcare professionals. They needed a chemical transfer pump that can handle abrasive and flammable fluids for emptying their cleaning tanks. Using our expertise, we specified a Flux F430 barrel pump with a 1500mm stainless steel shaft and ATEX motor, perfect for abrasive application and fitting into the tank.

On occasions, the required specifications don't make for a difficult selection. This company needed a pump suitable for chemicals, to be transferred from tank to tank with a low flow rate. Our selection was based upon the capabilities of the pump in question, and it's ability to slow down the flow rate to the desired range. This customer was happy with our suggestion and placed the order within 2 days of their initial enquiry.

Castle Pumps investigate all aspects of a customers requirements when specifying a pump, as it's essential to select the right pump for their needs. This case study shows that the customers requirements required further investigation in order for us to decide which pump would be best suitable for their requirements.

One of the UK's largest home fragrance manufacturers enquired about a pump for transferring wax at 60°C, which could do a number of batches within a set time frame. Due to prior experience, we knew which pump would be the best solution for their specific requirements and were able to supply an industrial peristaltic pump, that was low maintenance and relatively low cost.

A wood and laminate flooring company in the UK needed to gravity feed an adhesive from an IBC to a piece of machinery in their product line, in order to apply the solution in a particular way to their products. One of the main factors we had to consider was the thickness of the fluid - with a viscosity of 4000-5000 cP, we selected a gear pump which we knew could handle this type of fluid. Furthermore, by selecting a gear pump we were also able to achieve the low flow rate that the customer required.

A Nuclear Laboratory in the UK required a portable magnetic drive pump for transferring Zinc Bromide from IBC’s into radiation screens. The pump needed to be lightweight, fitted to a carry frame and have a single phase 110V motor. Castle Pumps has access to a high quality range of portable chemical transfer pumps and were therefore able to supply the customer with the required pump.

The Royal Veterinary College contacted us with a unique enquiry. They needed an ATEX rated hand pump for transferring -20°C acetone, which would be used to freeze animal carcasses in their laboratory. The college sent photos of the drum along with the dimensions, to ensure the tubeset was cut to the correct length. We supplied them with their required pump, as well as a discharge hose and nozzle so the customer had easier operation.

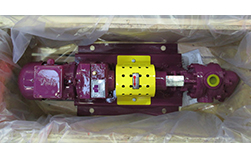

Castle Pumps pride themselves on providing perfect solutions to every customer’s requirements and this case study is a prime example. In addition to a quick turnaround, the customer needed a precise operating temperature, capacity and discharge pressure, and the fluid needed to maintain the same temperature whilst being pumped. Thanks to our extensive knowledge and experience, we provided the customer with a pump that matched their requirements just 32 days from their initial enquiry.

Castle Pumps' experience in the pump market means that the customer is always advised on the ideal type of pump for their application. In this example where a saline solution needed to be transferred slowly, Castle Pumps knew that a peristaltic pump was a perfect fit due to its low flow rate and the fact that the only wetted part that needs to be compatible with the solution was the hose.

Castle Pumps have a wide customer base including many manufacturing companies in different industries. As a result, there are very few liquids or pumped medium that we do not have experience in specifying a solution for. In this instance, the customer were struggling to find a pump for photopolymer resin, yet our experience knew that a progressive cavity barrel pump would be ideal.

Castle Pumps pride themselves on the slogan "Whatever the process, we have the pump". In this case study, the client had been informed by other suppliers that they were unable to source a circulating pump that could handle the extremely low temperature of -40ºC. Thanks to the wide range we have access to, we were able to find a pump that did the job and fulfil the customers requirements.

Castle Pumps are fully accredited to enable you to buy with confidence. Our accreditation includes:

![]() A division of the CTS Group, Part of Flow Max Ltd.

A division of the CTS Group, Part of Flow Max Ltd.