Boiler Feed for World's Largest Container Ship - Type Approved Centrifugal Pumps

Case Study Information

- Industry: Marine & Offshore

Customer: Shipping company

Application: Marine boiler feed water pumps

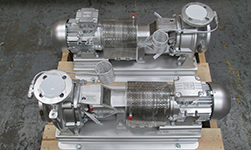

Equipment Supplied: 2 x Long coupled centrifugal pumps

Customer Location: UK

Equipment supplied

2 x Azcue AN Type approved long coupled centrifugal pumps

- Model: AN40-160HT

- Casing: Ductile iron

- Impeller: Bronze

- Twin bearing design

- Seal cooling system

Enquiry

Castle Pumps received an urgent enquiry for two marine boiler feed pumps required on board a TEU sized container ship for pumping high temperature water. The enquiry was a particularly interesting one as the vessel in question was the world's largest container ship when it was built in 2012. The customer needed the pumps complete with class certification urgently to ensure it could be installed when the ship next docked without having to stay there any later than scheduled and incur demurrage.

Key challenges:

Key challenges:

- Very urgent lead time

- Able to handle very high temperatures

Solution

Castle Pumps selected two AN type approved centrifugal pumps from Azcue; a specialist supplier when it comes to marine applications. The long coupled design of the AN model separates the pump from the motor allowing easier maintenance and also reduces the risk of any fluid entering the motor in the event of a mechanical seal failure. The twin bearing design also means that the strain of operation is shared, an important factor in increasing the life of continuously run centrifugal pumps.

To account for the high temperature of the boiler feed water, we specified a double mechanical seal cooling system which allows the handling of fluids up to 190 degrees C.

These centrifugal pumps were manufactured, assembled and witness tested in only 9 working days, ensuring delivery to the vessels next port of call in time. Our ability to fast track produce certain families of pumps ensures customers can count on Castle Pumps for support when it is most needed.

CMA CGM Marco Polo Vessel - The World's Largest Container Ship (2012)