Food Industry Pumps

Looking to upscale your food or beverage production and reduce costs in the process?

Looking to upscale your food or beverage production and reduce costs in the process?

If you’re in the food and drink manufacturing industry you’ll know just how many food processing pumps your plant relies on; for dosing specific quantities of ingredients in the production line, transferring the finished product into containers, removing any waste product leftover and even for cleaning chemicals.

With fluids varying from shear sensitive creams and syrups, to viscous, solid laden sauces to high temperature vegetable oils, the process of specifying a food grade pump requires many technical considerations. And that’s where we help.

Where Our Approved Food Safe Pumps Are Used

All of the food transfer pumps we supply to the industry are FDA approved meaning that food contact surfaces are smooth, free of crevices, non-absorbent, cleanable, non-toxic and corrosion resistant to ensure that no food or bacteria can harbour and contaminate the product. We typically find that FDA pumps are satisfactory for most manufacturers, however where the client wants more official compliance, we offer food grade pumps approved to 3A and EHEDG.

For food industry pump applications including:

- Sauces, syrups, soups and condiments

- Milk, cream, yoghurt and liquid egg

- Fruit juices, smoothies and sodas

- Beer, wine and spirits

- Edible oils and fats

- Dosing ingredients and additives

Common Problems Our Food Transfer Pumps Prevent!

- Contamination - FDA, 3A and EHEDG food safe pumps, Tri-clamp sanitary fittings and models with sanitary enclosures for added protection.

- Changes in Consistency – Low shear pumps to prevent delicate products e.g. cream being damaged or altered in terms of texture or taste.

- Crushing of Solids – Our peristaltic, flexible impeller and diaphragm pumps can transfer solids without clogging or turning them to mush.

- Inaccuracy – To ensure consistent and accurate dosing of ingredients we specify smooth, non-pulsing food processing pumps optional batch meter.

- Manual Intervention – We can improve your workers' productivity with control features such as dry run protection, level switches and batch meters!

- Product Wastage – Our food grade barrel pump range includes options capable of 99.8% container emptying to limit any expensive product waste.

- Excessive Wear – By selecting the right food grade pump for your application, regularly replacing spare parts will be a thing of the past!

Who We've Worked With in the Food Industry

Case Studies

Wine Transfer in Winery - Flexible Impeller Pump

We received an enquiry from a contract winemaker based in the UK. They required a food grade pump to transfer wine at temperatures between 2 and 65⁰C, with a maximum flow rate of 15,000 litres per hour and ideally the option of variable speed to enable more control. Due to the nature of their application and the specifications required, we supplied the Liverani All in One Flexible Impeller Pump which was a perfect fit for their requirements.

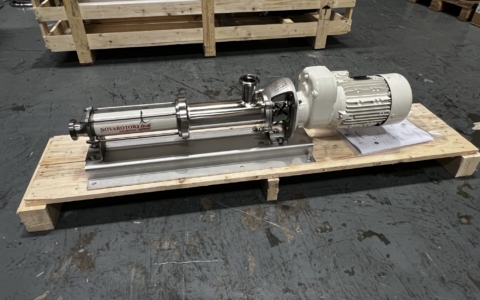

Soup Transfer – Food Grade Progressive Cavity Pump

Castle Pumps received an enquiry from a Stainless Steel fabricating company, who specialise in the design and manufacturer of equipment for the food processing equipment. A project they were commissioned to work on required a pump to be installed onto the equipment they were manufacturing, which we were happy to help specify. The pump was needed to transfer soup, which could contain both meat and vegetable pieces.

Transfer of Hot, Viscous Bolognese Sauce - Food Grade Barrel Pump

As well as pumps for industrial and marine applications, Castle Pumps can also supply pumps for the food grade market. This was a new customer that was enquiring about a pump to transfer Spaghetti Bolognese from production to packaging when hot. Castle Pumps visited site to get as much information as possible, and by using our extensive knowledge and past experience we were able to design a bespoke pump kit and supply all within five working weeks.