Ship classification isn’t just more red tape or another administrative burden; the marine industry place a large reliance on the official validation that a vessel and its key components meet regulatory, technical, safety and environmental requirements. It’s a lot more than just the “best practice” guidelines that are seen in other industries.

This article will explain the background of ship classification and the importance of sourcing type approved components for compliance, drawing on our area of expertise as an example - pumps.

An offshore vessel is required to be classified by certain bodies and organisations for confidence regarding the fitness of the ship. For example, insurance policies use it as an indication that the policy is less likely to need to pay out, banks granting a loan for the ship use it for confidence that repayments will be made. Without being able to present proof of classification, insurance of the vessel can be rejected and it may be unable to sail, dock at certain ports and enter specific waterways.

Classification also gives the ship owner or management company themselves assurance that the vessel is safe, reliable and fit for service and legally compliant, providing of course that it is loaded, operated and maintained in a proper manner by competent and qualified personnel.

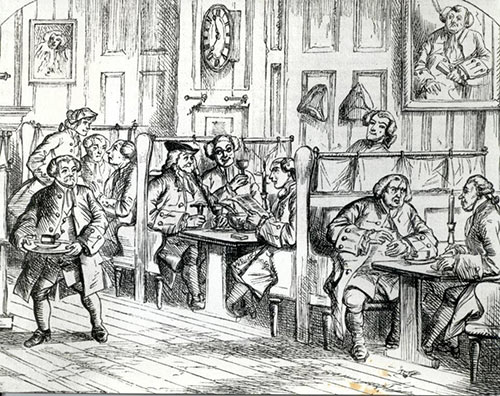

Classification of this kind dates back to the 18th century when marine insurers and merchants would gather in Lloyd’s coffee house in London. Edward Lloyd, the coffee house owner, began circulating all the news he heard in his printed bulletin that gave descriptions of ships looking for insurance. From this, a Committee was formed by the coffee house’s customers who developed a system for independently assessing ships for insurance. And so Lloyds Register was born.

Today, we see the International Association of Classification Societies (IACS) made up of 12 members worldwide including the original Lloyds Register and other leading societies such as ABS and Bureau Veritas, of whose rules and standards cover 90% of the world’s cargo carrying tonnage.

These classification societies essentially inspect, validate and report that a vessel has been constructed in accordance with relevant standards, and conduct regular surveys to ensure that compliance is continued throughout its operating lifespan (not just at construction!). They do this whilst remaining impartial and independent; the society must have no interest in the ship owner, ship builder or any other party commercially involved in the vessel and no third party influence can be present.

With ship classification covering the design and construction of the entire vessel, it isn’t just the hull that is inspected. Almost all critical components including materials used, engines and pumps need approving and therefore manufacturers whose products are used on board classified vessels must get them certified to meet the same technical standards or as the industry calls it “Type approved”. Given that pumps are our forte, let’s use these as an example…

Pumps play a core role on board a ship and performance failures can have catastrophic results:

A pump may be able to perform a service in theory, but may have been designed for an industrial application that are not subject to the adverse conditions at sea such as pitch and roll, humidity and other circumstances. Some designs of industrial pumps are not maintenable which is an undesirable situation when at sea.

Should a cooling pump being used in a manufacturing production line fails; the machine may overheat and cause the system to shut down which results in costly downtime for the company. This of course every company wants to avoid, but in comparison to a ship’s engine cutting out in the middle of the ocean with lots of people or cargo on board, the potential impact is much greater. Under general averaging maritime law the losses of any cargo can be shared amongst all the parties in the sea venture. Recently Shippers with cargo shipped on the fire-stricken Maersk Honam will have to stump up over half the cargo's value in order for it to be released under general average arrangements.

Given the above, failure to employ type approved pumps during ship construction or modernisation will affect its overall classification application and replacing an existing marine type approved pump with a cheaper, non-type approved pump can null your vessel’s insurance policy that has been granted on the basis of classification.

It is therefore vital when sourcing pumps for marine services that they have gone through the rigorous type approval process by a marine classification society to ensure technical and safety compliance for the intended use. The below is based upon Lloyd’s Register’s process:

Design Review - The design of the product is evaluated to see whether it complies with the agreed technical requirements.

Type Testing – Testing of the product under the conditions it will be used is undertaken to confirm the specified requirements are complied with. This is usually undertaken at an accredited lab, but where authorised can be at the manufacturer’s’ premises.

Production Quality Assessment – The place of production will be visited to ensure that the product can be consistently produced in compliance with the requirements, with consideration to the facilities, procedures, production equipment and quality policies.

**Reference Lloyds Register Type Approval System, Procedure TA14 Version 03 (July 2017)

Once a product has been granted type approved status, the manufacturer and their distributors can use the approval marks and classification societies’ logo to promote compliance on packaging, promotional literature and the product itself. When sourcing a type approved pump this is something to look out for and ask the supplier about if you cannot see it to prevent any delays in your vessel’s classification or problems with the insurance.

It is important that CE marking is not to be confused with type approval. CE marking is simply a declaration by the manufacturer themselves, that the item meets the minimum requirements of all laws applicable to it. As detailed in the detailed process above, type approval is by an independent, third party considering many more technical and engineering standards that the law dictates.

To provide confirmation and allow easy procurement by a vessel owner, ship management company or marine engineer that the components they are sourcing do indeed meet requirements, classification societies must publish a list of all type approved products.

As well as finding a type approved solution, consideration should also be given to the supplier you are purchasing it from. Are they well-established with experience in the marine field? Is there a network of agents with spares available worldwide and do they stock critical spares and pumps? Are spare parts available for the lifespan of the pump? Can they fast track requirements? Can the supplier provide a package of pumps under one warranty?

Whilst finding a quality manufactured, third party tested product is a large part of the procurement process, ensuring the supplier has the knowledge to closely match the pump’s duty to the application’s performance requirements will improve efficiency, limit wear and maintenance and reduce energy consumption.

Castle Pumps Ltd are a specialist provider and stockist of type approved pumping solutions by marine classification societies, and the UK agent for Azcue; a manufacturer with 100 years’ experience in pumps for the offshore industry. For more information, please take a look at our solutions brochure.

Castle Pumps Ltd are a specialist provider and stockist of type approved pumping solutions by marine classification societies, and the UK agent for Azcue; a manufacturer with 100 years’ experience in pumps for the offshore industry. For more information, please take a look at our solutions brochure that demonstrates the wide range of models within the range.

Castle Pumps are fully accredited to enable you to buy with confidence. Our accreditation includes:

![]() A division of the CTS Group, Part of Flow Max Ltd.

A division of the CTS Group, Part of Flow Max Ltd.