Ballast Water Management Solutions

With 51 states, representing over 35% of total merchant shipping tonnage formally accepting, the BWM regulations were introduced September 2017. To comply, new ballast water management systems will be required. Azcue pumps have been involved in over 10,000 vessel builds and are therefore a trusted solution for ballast applications. Contact us for a solution when updating your ballast system.

Ballast Water Management Regulations

Whilst ballast water is vital for the safe and efficient operation of modern ships, because of the potentially harmful marine species present, discharging untreated ballast water can lead to significant ecological and economic issues associated with spreading these outside of their native home. In response to this threat, the International Maritime Organisation (IMO) adopted the Ballast Water Management Convention.

As everyone in the maritime industry will now know, on 8th September 2016, Finland joined the other 51 states that had formally accepted the Ballast Water Management Convention proposed by the IMO, who together equated to 35.14% of the world’s merchant shipping tonnage. With the treaty stating that ballast water management would become mandatory once at least 30 states, representing 35% of total merchant shipping tonnage were in agreement, the convention officially came into force a year later. So, what exactly does this mean for the industry? And what do ship owners need to do?

What do shipowners need to do, and when?

The BWM convention includes two performance standards regarding the discharge of ballast water; D1 and D2. The D1 requirements, which state that ballast water exchange must be undertaken within open ocean areas at least 200 nautical miles from land, in waters at least 200m deep, were enforced for all existing vessels from the date of entry; 8th September 2017. However, as D1 is not considered an ideal solution, the D2 standards, which specify the maximum number of organisms allowed to be discharged, is the long-term requirement with a phased implementation.

All new vessels built since 8th September 2017 must already comply with the IMO’s Ballast Water Management D2 requirements of an on board ballast water treatment system to reduce the marine species discharged into the sea. This means that any future ship must consider the new regulations during construction as they will need to comply at delivery.

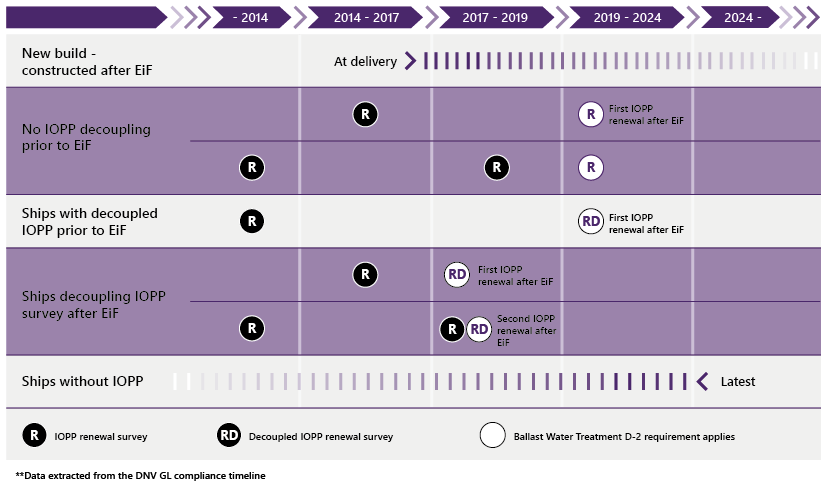

The deadlines for all existing ships’ implementation are between now and 8th September 2024, depending upon their next International Oil Pollution Prevention Certificate (IOPP) renewal survey date. For many shipowners, this requires a complete upgrade of the existing ballast water system on board their vessel. To help shipowners determine when they need to comply, the DNV GL have published their compliance timeline.

Not sure on your deadline? Take a look at the DNV GL compliance timeline below.

Whatever a vessels’ D2 compliance date, compliance is inevitable and ship owners need to consider their ballast water management system implementation plans now to prevent penalties. Castle Pumps have already helped many vessels with the specification and supply of ballast pumps for both the transfer and discharge of the seawater during a ballast water system upgrade. We welcome you to send our technical sales engineers your ballast pump enquiries at sales@castlepumps.com or +44(0)1773 533 283.

Ballast water pump solutions

Having been installed in over 10,000 vessel builds, Azcue pumps are a trusted solution for new ballast water system installations.

- Marine type approved by classification societies

- Cast in bronze; shorter lead times & cheaper than stainless

- Up to 5000m³/hr and 190m for all ballast tank sizes

- Priming pumps for complete emptying of the ballast tank

- Space saving vertical inline design for when space is an issue

- Fast track production to avoid demurrage & costly downtime

- A minimum of 15 years’ spares supply for long term servicing