Castle Pumps: Your Process Delivered

Popular Pump Types

View all pump typesCase Studies

View all case studies

Wine Transfer in Winery - Flexible Impeller Pump

We received an enquiry from a contract winemaker based in the UK. They required a food grade pump to transfer wine at temperatures between 2 and 65⁰C, with a maximum flow rate of 15,000 litres per hour and ideally the option of variable speed to enable more control. Due to the nature of their application and the specifications required, we supplied the Liverani All in One Flexible Impeller Pump which was a perfect fit for their requirements.

Lamella Settlement Tank Emptying - Peristaltic Pump

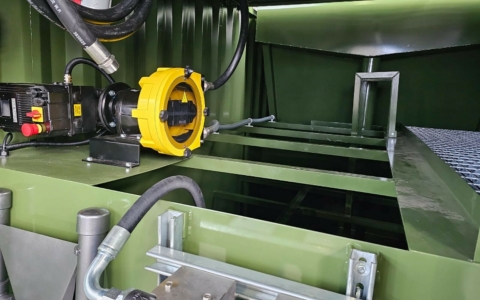

We received an enquiry from Northern Tanks, a fabricator of fluid storage tanks and transfer systems. They were in the process of a designing a steel container which would enclose a water tank with pressure washers connected, used to wash down site equipment. Once used, the collected water would be passed through a Lamella Separator and Filter to remove any large solid particles and returned to the original water tank to use again.

Vape Flavour Dispensing from IBCs - Food Grade Barrel Pump

Castle Pumps received an enquiry from a manufacturer of vape liquids and flavours who were looking to upscale their production. Part of this involved improving the efficiency of transferring the concentrated flavours from the IBCs where they are stored. The customer was looking for a number of container emptying solutions for fitting onto the IBCs and dispensing the favours without manually handling the fluid. They were looking for a number of container emptying solutions for fitting onto IBCs.