Information Hub

Whether you buy, specify, maintain or operate pumps, you will find something useful to you in our Information Hub.

Centrifugal Pump Maintenance Schedule

Centrifugal pumps are one of the most popular pumping solutions in the world but, just like any other pump, to keep centrifugal pumps running smoothly you need to implement a preventive maintenance schedule. To help you put together your centrifugal pump maintenance schedule, we asked our technical sales engineer for advice. Read the article to see their recommendations.

Is Your Pump Costing Too Much of Your Engineers’ Time?

As labour costs are one of the most expensive overheads in any company, you need to consider the time your engineers spend on your existing processes. Pump maintenance can be one of these processes, so to make sure that you’re not spending more time than necessary read this article and find the four avoidable signs that your pumps may be costing your engineers’ time.

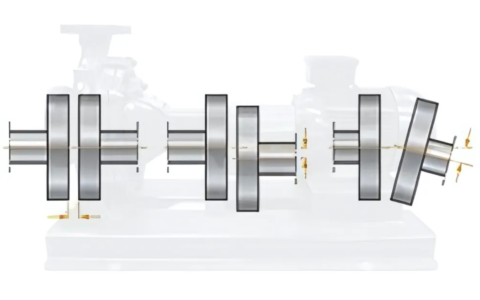

Pump Couplings – A Comparison of Rigid, Flexible & Magnetic

Understanding pump couplings - a complete guide. In this article we discuss everything you need to know about couplings; from what a coupling is, to the three different types available and the performance of each type. We also talk about the issue of misalignment, a factor which should always be considered when deciding which coupling is the right one for your application.

Centrifugal Pump Impellers – The Types & Their Impact

Impellers are an integral part of a centrifugal pump's operation. They come in varying shapes and sizes, offer an array of performance characteristics and are individually suited to different applications. Find out about the different types of impeller, the impact of diameter and what other factors need to be considered when choosing the right centrifugal pump for your process.

Typical Problems the Wrong Pump Can Cause Your Process

With so many pumping technologies and pump types, how do you know that you have the right pump for your process? Castle Pumps have extensive product knowledge and know typical scenarios where getting the wrong pump can result in expensive downtime and imperfect product. Read the article to learn more about how you can avoid these typical issues and select a more efficient pump that fit your process.

Automating Your Pump to Reduce Manual Operation

Labour costs are one of the most expensive overheads in any company. So are your engineers spending more time than necessary on operating the pump? If, so it is time to consider automating your pump and freeing up your employees' time for more value-added tasks and making your process more efficient. Read our article and find more about how you can automate your pump and how your process can benefit from pump automation.

The Importance of Considering a Pump’s Total Life Cycle Cost

When selecting a pump, businesses are often faced with budgetary pressures, which affect their decision and make them choose not the most economical solution in the long term. Considering the upfront/initial costs without understanding the future running costs is a common mistake. To make sure you are buying a pump with the lowest long term cost, read this article and find more about the total life cycle cost of a pump.

7 Ways to Improve the Energy Efficiency of Your Pump

The environmental impact of activities, products and services is measured and monitored now more than ever, especially within the marine and industrial markets. This along with the ever increasing need to reduce costs, means energy efficiency is an important factor - especially where your pumping system is concerned. In this article we discuss 7 ways that you can improve the energy efficiency of your pump...

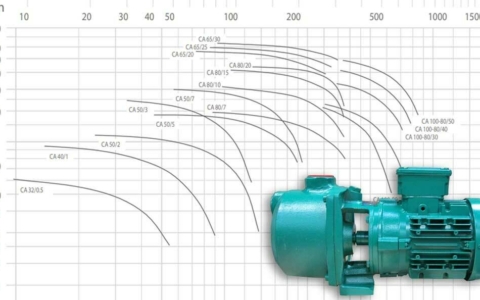

How To Read the Pump Curve of a Centrifugal Pump

Pump curves are essential during the decision making process, as they provide the information you need in order to see whether the pump will perform how you need it to! In their most basic form, performance curves contain flow rate and pressure data. Being able to read a pump curve enables you to choose the right pump, rather than choosing one that could potentially cause damage, consume unnecessary energy or perform poorly.

How to Calculate Head Loss in a Pumping System

Head loss is an essential part of the preparation of looking for a pump with specific requirements. These head losses - also known as pressure losses - are sustained by the fluid as it flows through the pump and therefore can affect the pumping operation. Being such an important factor when making the decision on which pump to purchase, we have created this section for you to calculate the head loss within your application.

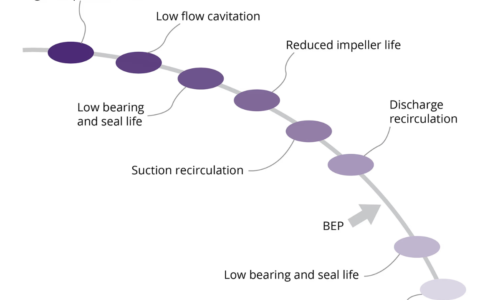

Best Efficiency Point of a Centrifugal Pump

If you operate, maintain or specify centrifugal pumps then you will likely have heard of a pump curve. However, what many misses to consider is the best efficiency point of the pump they are selecting, which can result in costly maintenance and downtime. So, read this article and learn more about what BEP is and what happens to your pump when you operate it too far left/right of the pump curve.

Pressed Metals vs Cast Metals

There are a number of differences between cast and pressed metals, but do you know how they could affect your decision when buying a pump? This article explains in depth what each type means as well as the pros and cons, so that you know which bits of information you should take into account when deciding on the best pump for your individual process at hand.