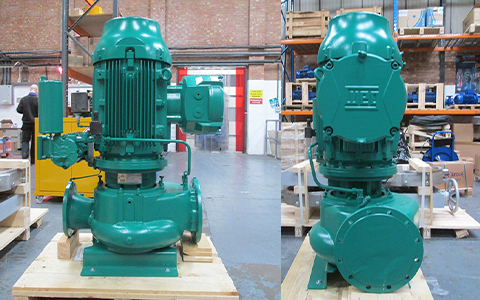

Azcue VM & VR Vertical Inline Centrifugal Pump

Fire Fighting Pump & Sea Water Cooling Pump

| Key Specifications | |

|---|---|

| Max Flow Rate | 1500M³H |

| Max Head | 130M |

| Max Temperature | 130°C |

| Max Viscosity | 200 cP |

| Solids | 0mm |

| Size | DN50-250 |

The Azcue VM & VR Vertical Inline Pumps are larger, heavier duty vertical centrifugal pumps, with larger flow and pressure capabilities than the LN. They are ideal solutions for applications involving relatively clean liquids such as water and thin fuels, where space saving may be important. Unlike the VM, the VR single stage centrifugal pump has an additional ball bearing between the pump and motor to share the strain of operation, making it the more robust of the two within critical applications.

The Azcue VM/VR vertical inline centrifugal pump is a back pull out model, which means that the motor is able to be removed from the pump without having to completely disconnect the pump from the installation; a great time saving benefit during maintenance. Although technically close coupled, these centrifugal water pumps have a lantern bracket that provides space between the pump and motor whilst still being compact. This means that if the seal wears, no fluid will fall into the motor. This model has wear rings, which means there is small clearance between the impeller and pump casing ensuring the parts are not subjected to wear. Wearing rings are designed to be replaced periodically, preventing the more costly replacement of the impeller or casing.

These Azcue vertical inline pumps have separate shafts in the pump head and motor meaning that if one there is ever an issue with one shaft, there is no need to replace it all; a benefit over other pumps on the market that have one continuous shaft from head to motor. The VM and VR close coupled centrifugal pumps can be supplied with an external vacuum or electric priming pump. When suction conditions are more difficult, a vacuum priming pump should be picked thanks to its ability to dry run for short periods of time.

Features of the Azcue VM/VR Vertical Inline Pump:

- Close coupled, single stage vertical centrifugal pump

- VR version has additional bearing between pump and motor to share strain

- Pump manufactured in Spain

- Marine type approved by all classification societies

- Compact vertical design ideal for space saving installations

- Available in cast iron, 316 stainless steel and bronze for seawater

- Lantern bracket providing some space between pump head and motor

- Back pull out design for simple maintenance

- Separate shafts in the pump and motor

- Low NPSH

- Casing wear rings to prolong casing and impeller life

- 230v, three phase 50Hz/60Hz motors available. IP55 as standard.

- Available with a vacuum or electric priming pump on request

- ATEX version available

- Supplied flanged as standard

The VM & VR Vertical Inline Centrifugal Pump is manufactured by Azcue Pumps. As the official UK Agent of Azcue Pumps, Castle Pumps are a leading Bombas Azcue supplier in the UK with unrivalled technical knowledge. Azcue Pumps are a European manufacturer with over 100 years’ experience in type approved pumps for marine and offshore applications. Today their pumps are installed in more than 10,000 vessel builds. Whilst originally developed for the marine market, Azcue Pumps’ reliability in applications that depend upon the safety and operation of a ship saw them become a desirable product in industrial applications involving water, fuels and lubricants.

One of the key benefits of the VM & VR vertical inline pump like the other models in the Azcue range, is that is benefits from interchangeable parts for reduced on board stockholding. We guarantee supply of spares for 15 years from model discontinuation for long term pump servicing., saving the user from having to prematurely replace a pump that just needs maintenance.

Azcue VM & VR vertical centrifugal pumps are cast, machined and assembled at their foundry in Spain. Each pump is manufactured to order and designed to fit your process, resulting in greater efficiency and lower overall lifetime cost in terms of wear and energy consumption. Before leaving the factory, pumps are individually tested to confirm performance meets the requirements set out in your enquiry.

Single stage centrifugal pumps are the most common pump type for the transfer of low viscosity fluids in high flow rate and relatively low-pressure installations. The centrifugal pump design is often associated with the transfer of water, but is also a popular solution for handling thin fuels and chemicals. This combined with its motor being located above the pump head, makes the Azcue VR & VM vertical inline pump suited to applications where installation space may be limited including:

| Marine Applications: | Industrial Applications: |

|

|

The Azcue VM & VR vertical inline close coupled centrifugal pumps are available with the following material options:

| CAST IRON GG25 | BRONZE G-Cusn5ZnPb (Rg5) | BRONZE G-CusN10 | BRONZE G-CUA110Ni | BRONZE G-CuSN10Zn (Rg10) | STAINLESS STEEL AISI 316 X5CrNiMO 18 10 | STAINLESS STEEL AISI 420 X20Cr13 | |

| VOLUTE | X | X | X | X | X | X | X |

| IMPELLER | X | X | X | X | X | X | X |

| SHAFT | X | X | |||||

| WEAR RINGS | X | X | X |

Ballast Water Transfer for Vessel - Vertical Inline Pump

Castle Pumps have built solid relationships with many industrial pump manufacturers, which gives us confidence in our ability to meet tight project time scales. This case study illustrates this, where we were able to get two ballast pumps manufactured and marine certified in three weeks less than the industry standard lead time.

Ballast Water System Upgrade - Vertical Inline Centrifugal Pumps

Castle Pumps received an enquiry from a new customer who needed to upgrade their ballast water system, in order to meet the 'Ballast Water Management Convention 2017' regulation. We supplied Azcue cast bronze pumps to ensure that all wetted parts that come into contact with the seawater are non-ferrous and therefore would not corrode. Ballast water pumps transfer seawater to and from the ballast tanks in order to add weight to the ship for stability, so reliability is key.

Model Codes

Description

VM 50/16

VM 50/20

VM 50/26

VM 50/33

VM 65/26

VM 80/16

VM 80/20

VM 80/26

VM 80/33

VM 80/40

VM 100/20

VM 100/26

VM 100/33

VM 125/20

VM 125/26

VR 80/26

VR 80/33

VR 100/26

VR 100/33

VR 125/40

- VR 125/50