Case Studies

With over 15 years' experience specifying and supplying pumps, we have probably delivered a solution like yours before. Take a look at just some of our past projects.

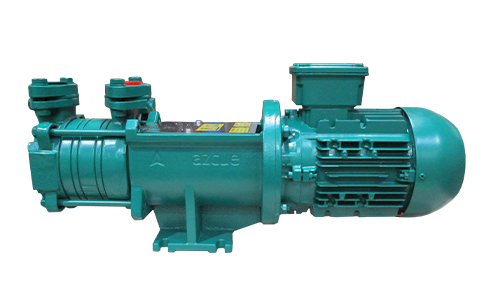

Seawater A/C Cooling for Offshore Support Vessel – Vertical Inline Pump

Castle Pumps received an enquiry from a regular maritime logistics customer who has over 90 vessels - a lot of which have Azcue pumps installed onboard already. One of their tug supply vessels needed to replace some existing seawater cooling pumps for the onboard air conditioning system. We supplied some vertical inline pumps suitable for use with seawater and which matched their existing dimensions and performance requirements.

Beer Transfer at Brewery - Hygienic Flexible Impeller Pump

We received an enquiry from this brewery company in Scotland who required a portable hygienic pump for the transfer of beer within their factory. We decided the best option would be a food grade flexible impeller pump with tri-clamp connections in order to meet the necessary standards within the food industry. The customer was that happy with their pump that they sent us some beers to show us what the pump would be helping to produce.

Fresh Water Pumping for Civil Engineering - Vertical Inline Pump

This customer required a high flow fresh water transfer pump which would be free from corrosion and therefore keep the water contaminant free. We selected a bronze pump which we knew would be able to handle this type of fluid without any complications. We also decided to couple the pump with an electric 4 pole motor running at 1450 RPM which would increase the lifespan of the pump and the wearing components in the pump, which in time, reduce overall costs.

Abrasive Waste at Chicken Factory - Vertical Immersion Pump & Vortex Impeller

This customer was having daily issues with a pump brought from another supplier. The pump, which was transferring blood, water and feathers; was clogging every day, halting production and costing them £0000's in downtime. We decided to visit the site to get a greater understanding of the customer's requirements. From there, we came up with a pumping solution fit for purpose, which has been running for over 3 months (& counting) clog free.

Fuel & Coal Dust Slurry for R&D - Progressive Cavity Pump

A new customer approached us that needed a pump for an abrasive slurry of fuel oil and coal dust. The pump needed a low flow rate and the ability to handle abrasive coal dust, whilst also needing to be controlled by a variable speed drive for testing purposes. We supplied a progressing cavity pump as its properties and capabilities were the best match for the requirements, as it is this type of pump is really good when handling solids or abrasive liquids.

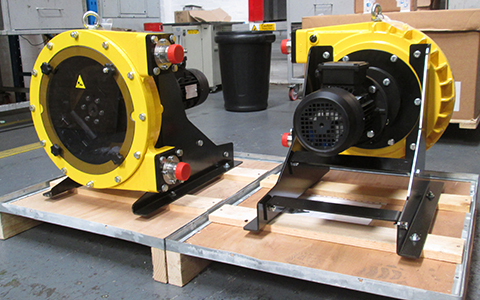

Emptying Toilet Waste Onboard Highland Railways - Peristaltic Pumps

Castle Pumps are always on hand to provide a solution to your pumping problems. This company contacted us because their current pumps were not performing as they should and kept getting clogged up. Space was also an issue for this customer, however, we were able to supply an ideal pump for their application which we adapted to minimise the footprint and provide an easy installation process, and minimise maintenance costs overall.

Sea Water Injection - Long Coupled Self Priming Centrifugal Pumps

Castle Pumps are able to supply pumps for both marine and industrial applications, and pride themselves on supplying pumps that best match the customers requirements. This enquiry was for self priming sea water injection pumps but the customer requested that the material be stainless steel 316, rather than the recommended material of bronze. We were able to provide a suitable pump that matched the customers requirements and which came in the requested material of stainless steel.

Emergency Seawater Circulation Pump Replacement for Subsea Support Vessel

Castle Pumps are committed to providing the best possible support and service to customers, so when an emergency pump is required, we strive to provide one in a preferable time frame. An enquiry for an emergency replacement pump was received after hours on a Friday, needed for installation Monday morning whilst the vessel docked. By working out of hours and supplying from our 'from stock' range, we were able to deliver on time.

Tank to Tank Transfer for Chemical Manufacturer - Peristaltic Pumps

On certain occasions, the required specifications don't make for a difficult selection. This company needed a pump suitable for chemicals, to be transferred from tank to tank with a low flow rate. Our selection was based upon the capabilities of the pump in question, and it's ability to slow down the flow rate to the desired range. This customer was very happy with our suggestion and placed the order for the exact pump within two days of their initial enquiry.

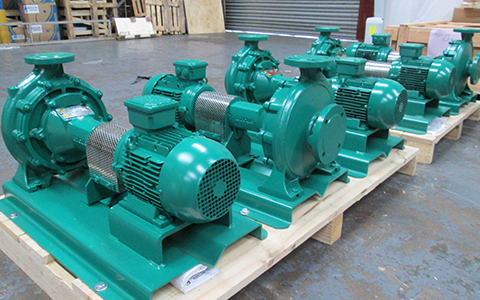

Seawater Cooling of Subsea Oil Rig Winch - Long Coupled Centrifugal Pumps

Here at Castle Pumps we understand that timing is important within the marine and offshore market. Quite often we receive enquiries that need to be dealt with quickly in order for the purchase and delivery to follow suit and minimise lead time. This subsea oil and gas company needed five sea water cooling pumps on a quick lead time. For this customer, we provided five long coupled centrifugal pumps in less than five weeks.

Seawater Containing Fish Waste at Fishery - Immersion Pump & Vortex Impeller

Some of the enquiries we receive here at Castle Pumps are straight forward and give us all the information that we need to specify a pump. This fishery company enquired asking us for a specific type of pump and told us the exact fluid and contents that they'd be pumping. This information enabled us to proceed quickly with our recommendation and then onto the manufacture and supply of the pumps.

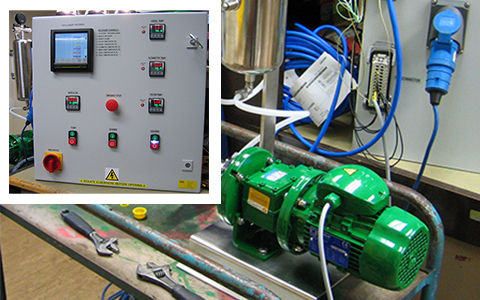

Seawater Draw & Circulation for Aquaculture - Self Priming Centrifugal Pump

Castle Pumps receive a wide range of enquiries for a number of industry applications. Farming fish on land is an unusual but increasing market which Castle Pumps have adapted to in order to specify and supply pumps for requirements posed for within this market. A centrifugal pump was selected to match their requirements, which was fitted with accessories and a bespoke control panel to ensure all of their specifications were met.