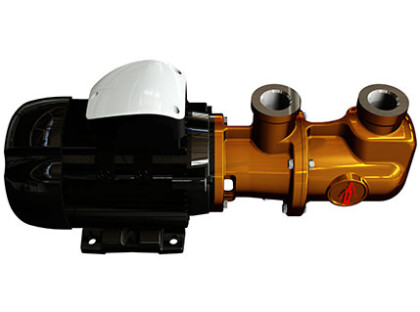

Nova Rotors R Wobble Progressive Cavity Pump

Sludge Pump & Viscous Fluid Pump

| Key Specifications | |

|---|---|

| Max Flow Rate | 233lpm |

| Max Head | 40M |

| Max Temperature | 80°C |

| Max Viscosity | 5000 cP |

| Solids | 10mm |

| Sizes Available | 1" to 3 1/2" |

The Nova Rotors R series progressive cavity pumps, also known as wobble pumps, are designed for applications where a compact design or lower flow rate is required, whilst still having relatively high pressure capabilities. The Nova Rotor wobble pump range includes the standard R models and then the RL series, which comes with three fluid discharge points and a patented join for absorbing the axial forces.

The R series of helical rotor pump can handle a wide range of different fluids including those that are slightly abrasive, viscous and contain solids in suspension, as well as shear sensitive mediums thanks to its non-pulsating flow. As well as cast iron, these progressing cavity pumps can come with a stainless steel casing for food grade applications or bronze for marine applications. Popular applications of the wobble pump range include oily sludge transfer, bilge water transfer, sewage transfer, fuel transfer and alcohol transfer, making is a very versatile pumping solution.

For more information on the design of this pump and its typical applications read our progressing cavity pump guide here.

- Low pulsations for handling shear sensitive products

- No vibrations

- Very high priming capability

- Capable of pumping fluids containing solids in suspension

- Capable of handling viscous fluids

- Lightweight and compact design in comparison to traditional progressive cavity pumps

- Available in stainless steel for food grade applications

- Bypass valve or pressure relief valve available

- RL series with patented joint absorbing most of the axial forces ensuring long lifespan

- RL series available with multi porting arrangement

- 230v, three phase 50hz / 60hz motors available

- Marine certification available

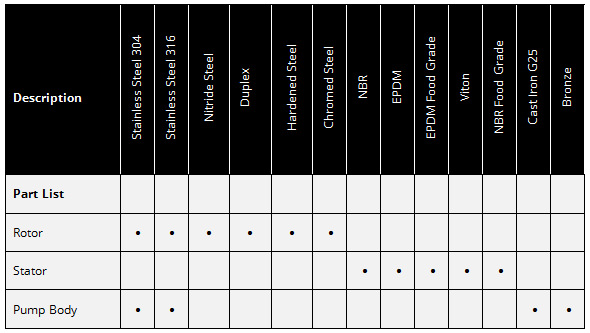

The Nova Rotors R series progressive cavity pumps are available with the following material options:

Lubrication Dosing for Decking Manufacturer - Progressive Cavity Pump

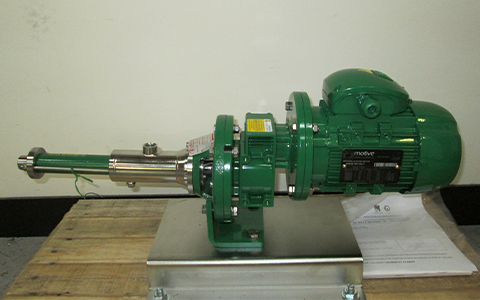

Castle Pumps pride themselves on being able to specify and design solutions to meet individual customer needs. This case study demonstrates this, where in order to meet the adjustable flow rate requirements of dripping lubricants onto wood fibres, Castle Pumps ensured that a motor variator was added to the unit to control the speed of the pump.

Fuel Transfer for Fuel Filtration/Cleaning OEM - Progressive Cavity Pumps

Our customer, a Fuel Cleaning OEM, was having trouble expanding the capacities of their fuel cleaning systems and required pumps that were not readily available from their previous supplier. They required a close coupled progressive cavity pump with integral relief valves to produce certain flow rates and pressures, and needed it in multiple voltages. Castle Pumps were able to offer the Nova Rotors Wobble Pump Series, which matched all of their requirements.

Sewage Discharge for Leisure Yacht - Progressive Cavity Pumps

An engineering company who were refurbishing a leisure yacht needed pumps for the sewage and oily waste water tanks, but were having trouble sourcing surface mounted self-priming pumps that would fit into the allocated space, that would perform the required duties. Castle Pumps came up with a solution and provided them with a unique range of progressive cavity pumps that matched their requirements and delivered them to the engineers in just over four weeks.

FAQs

It consists of a spiralled helical rotor (like a cork screw) that sits tightly inside a rubber stator/sleeve. As the rotor turns inside the stator, it forms a set of fixed-shaped cavities that progress along the length of the stator and force the fluid inside to move along with them as they turn.

Their pressure capabilities and viscosity handling is unrivalled, which means that whilst they are quite expensive in design and large in footprint, they are often selected for applications when all other pumping technologies will fail.

The design is best suited to highly viscous and lubricating fluids including oils, sludges, waste matter, biomass, pastes and grape pressing that may contain very large solids, as well as pumping viscous products over long distances.

Yes! A progressive cavity pump's tight tolerances mean it has excellent suction capabilities.

Yes they have excellent solid handling capabilities! However, it should be noted that abrasive fluids e.g. low viscosity/water based fluids containing solids may cause shorter stator wear.

Our progressing cavity pumps can be supplied with auger feed allowing non-flowing mediums such as dry sludge and waste matter to be pumped without clogging. We can also provide liquid injection ports which are popular when liquid waste is added to dry content waste to allow it to flow.

No! Even short period of dry running can result in damage to the rotor and stator, making dry run protection a must if there is risk of this.